Non-destructive helium leak detector for battery cover plates

Key words:

Non-destructive helium leak detector for battery cover plates

Product Details

Device Introduction

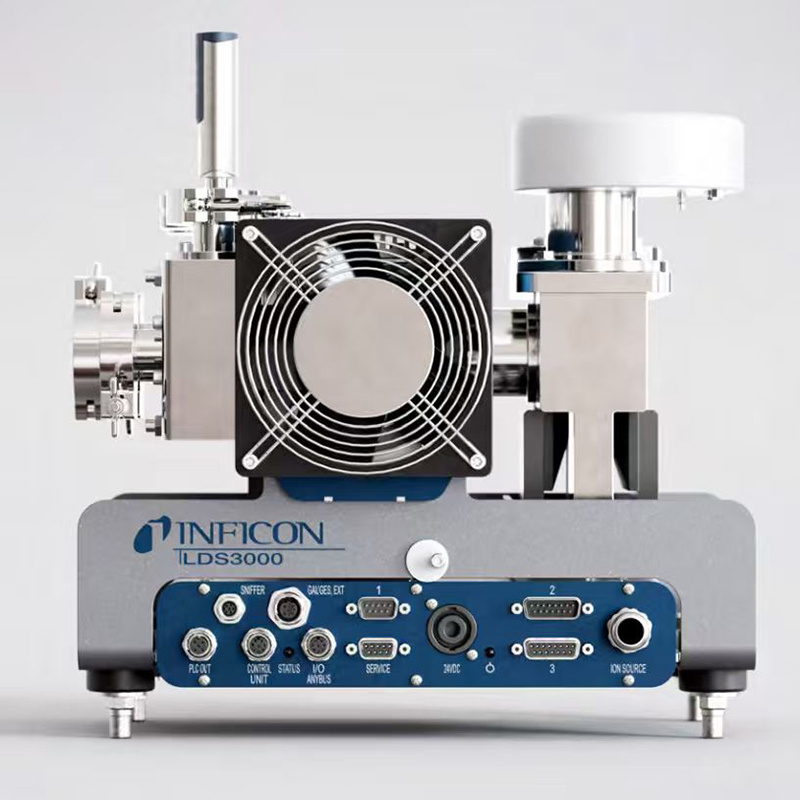

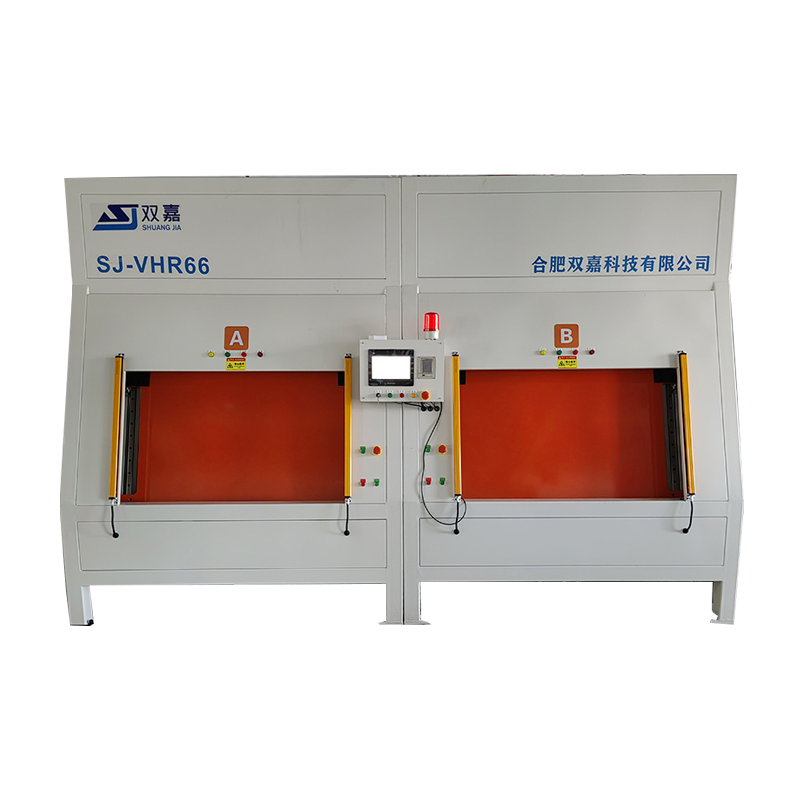

This device performs dry, non-destructive helium leak detection on battery covers. It uses a vacuum chamber method to evacuate the vacuum chamber, ensuring that the product is not affected by external interference. A certain pressure of helium gas is introduced into the product, and a helium mass spectrometer leak detector is used to test for helium leaks in the product. The vacuum chamber is evacuated to a pressure of less than 20Pa, and the leak detection accuracy can reach 5.0E-9Pa·m³/s. Operation method: Manually place the material in the designated position, and the robotic arm automatically grabs and places it into the vacuum chamber.

Related Products

Product Consulting

Welcome to leave us a message, we will contact us as soon as possible!