Information Details

How Integrated Helium Leak Detection Machines are Transforming the Future of Packaging Testing

How Integrated Helium Leak Detection Machines are Transforming the Future of Packaging Testing Table of Contents 1. Introduction to Helium Leak Detection in Packaging 2. Understanding the Technology Behind Integrated Helium Leak Detection Machines 3. Key Benefits of Using Helium Leak Detection Machines in Packaging 4. Applications of Helium Leak Detection in Various Industries 5. Recent Advancemen

Release time:

2025-08-17

How Integrated Helium Leak Detection Machines are Transforming the Future of Packaging Testing

Table of Contents

1. Introduction to Helium Leak Detection in Packaging

2. Understanding the Technology Behind Integrated Helium Leak Detection Machines

3. Key Benefits of Using Helium Leak Detection Machines in Packaging

4. Applications of Helium Leak Detection in Various Industries

5. Recent Advancements in Helium Leak Detection Technology

6. Implementing Integrated Helium Leak Detection in Your Packaging Line

7. Challenges and Solutions in Helium Leak Detection

8. The Future of Helium Leak Detection in Packaging Testing

9. FAQs: Helium Leak Detection Machines

10. Conclusion

Introduction to Helium Leak Detection in Packaging

In today's fast-paced manufacturing environment, ensuring the integrity of packaging is paramount. Consumers demand high-quality products with uncompromised safety standards. **Helium leak detection** has emerged as a game-changing technology that meets these demands with precision. Integrated helium leak detection machines utilize helium—a small, inert gas that easily penetrates materials—to identify leaks in packaging. This article delves into how these machines are revolutionizing the packaging testing landscape, ensuring products remain safe and effective from production to delivery.

Understanding the Technology Behind Integrated Helium Leak Detection Machines

Helium leak detection technology operates on the principle of **mass spectrometry**. By introducing helium into a package under test, the machine monitors for any helium that escapes. The detection system analyzes the concentration of helium ions and determines the presence and size of leaks with remarkable accuracy.

**Integrated helium leak detection machines** combine this technology with automation, enabling real-time monitoring and reporting. This integration allows for seamless operation within the packaging lines, minimizing downtime while maximizing efficiency. The advanced algorithms used in these machines enhance their sensitivity and specificity, making them indispensable tools in various industries.

The Components of Helium Leak Detection Systems

Helium leak detection systems typically comprise several key components:

1. **Helium Source**: Supplies the helium gas for testing.

2. **Test Chamber**: Contains the package during the leak detection process.

3. **Mass Spectrometer**: Analyzes the helium concentration in the chamber.

4. **Control Unit**: Manages the operation of the system and processes data.

5. **User Interface**: Displays results and allows operators to interact with the system.

This sophisticated setup ensures that manufacturers can conduct thorough leak tests efficiently and accurately.

Key Benefits of Using Helium Leak Detection Machines in Packaging

The integration of helium leak detection machines offers multiple advantages for manufacturers across various sectors:

1. Enhanced Accuracy

Helium leak detection is highly sensitive, capable of detecting even the smallest leaks. This level of accuracy is crucial for industries such as pharmaceuticals and food packaging, where product integrity is non-negotiable.

2. Increased Efficiency

Automated systems enable manufacturers to conduct tests rapidly, reducing time spent on manual checks and ultimately speeding up production lines. This efficiency translates to lower operational costs.

3. Versatility in Application

Helium leak detection can be applied to various types of packaging materials, including plastics, metals, and composites. This versatility makes it a preferred choice for diverse industries.

4. Minimal Environmental Impact

As helium is a non-toxic and environmentally friendly gas, the use of helium leak detection presents a safe alternative to traditional methods that may involve hazardous substances.

5. Improved Product Quality and Safety

By ensuring packages are leak-free, businesses can maintain high product quality and safety standards, leading to increased customer satisfaction and loyalty.

Applications of Helium Leak Detection in Various Industries

Helium leak detection technology finds applications in numerous sectors. Here are some of the most prominent industries leveraging this technology:

1. Pharmaceutical Industry

In the pharmaceutical sector, ensuring the integrity of drug packaging is critical. Helium leak detection helps confirm that sterile products remain uncontaminated and effective throughout their shelf life.

2. Food and Beverage Industry

Food packaging must prevent contamination and spoilage. Helium leak detection ensures that seals are intact, preserving freshness and safety for consumers.

3. Electronics Industry

Sensitive electronic components require protective packaging to prevent moisture ingress and damage. Helium leak detection guarantees that packaging maintains its integrity even in challenging environments.

4. Automotive Sector

In automotive manufacturing, components like fuel tanks and air conditioning systems must be leak-proof. Helium leak detection provides an effective solution for ensuring product reliability.

5. Medical Devices

Medical devices often rely on airtight packaging to maintain sterility. Helium leak detection plays a vital role in confirming that these devices are safe and ready for use.

Recent Advancements in Helium Leak Detection Technology

As technology evolves, so does the field of helium leak detection. Recent advancements have introduced more sophisticated systems that enhance both functionality and user experience.

1. Portable Helium Leak Detectors

The development of **portable helium leak detectors** allows for on-site testing, providing manufacturers with flexibility and convenience without compromising accuracy.

2. Cloud-Based Data Management

Modern helium leak detection systems now offer cloud connectivity, enabling real-time data analysis and reporting. This feature allows for enhanced monitoring of production quality and quicker decision-making.

3. Integration with Industry 4.0

The integration of helium leak detection machines with Industry 4.0 technologies facilitates seamless communication between machines, enhancing overall manufacturing efficiency.

4. AI and Machine Learning Applications

The application of AI and machine learning algorithms in helium leak detection improves predictive maintenance capabilities, helping manufacturers preemptively address potential issues before they escalate.

Implementing Integrated Helium Leak Detection in Your Packaging Line

Implementing helium leak detection technology in your packaging line requires careful consideration and planning. Here are key steps to ensure a successful integration:

1. Assess Your Needs

Identify the specific requirements of your packaging process. Consider factors such as the types of products being packaged and the necessary sensitivity levels for leak detection.

2. Choose the Right Equipment

Select helium leak detection machines that best fit your operational needs. Evaluate various manufacturers, focusing on reliability, service support, and technology features.

3. Train Your Team

Proper training is essential for staff to operate helium leak detection machines effectively. Ensure that your team understands the technology and its impact on product quality.

4. Develop a Maintenance Plan

Regular maintenance of the detection systems is crucial for optimal performance. Establish a routine maintenance schedule to minimize downtime and ensure consistent accuracy.

5. Monitor and Analyze Data

Utilize the data generated from helium leak detection to monitor trends and identify areas for improvement in your packaging processes. Continuous analysis will help refine operations and enhance product quality.

Challenges and Solutions in Helium Leak Detection

While helium leak detection offers numerous benefits, certain challenges may arise during its implementation.

1. High Initial Costs

The initial investment for integrated helium leak detection machines can be significant. However, the long-term savings from reduced product recalls and improved efficiency often outweigh these costs.

2. Training Requirements

Ensuring that staff are adequately trained to operate sophisticated leak detection machines can take time and resources. Investing in comprehensive training programs is essential for maximizing the technology's benefits.

3. Equipment Calibration

Regular calibration is necessary to maintain the accuracy of helium leak detection machines. Establishing a routine calibration schedule will help mitigate this challenge.

4. Environmental Considerations

Helium is a finite resource, and improper handling can lead to wastage. Implement best practices for helium use and explore recycling options to minimize environmental impact.

The Future of Helium Leak Detection in Packaging Testing

The future of helium leak detection in packaging testing looks promising, with ongoing advancements in technology paving the way for more efficient and effective solutions. As industries continue to emphasize quality and safety, the demand for reliable leak detection methods will only grow.

Innovations such as **robotic integration**, enhanced automation, and further advancements in AI are expected to reshape the landscape of packaging testing. As manufacturers embrace these technologies, helium leak detection will remain a cornerstone of quality assurance in packaging.

FAQs: Helium Leak Detection Machines

1. What is helium leak detection?

Helium leak detection is a method used to identify leaks in packaging by introducing helium gas and measuring its concentration in a designated test chamber.

2. How accurate are helium leak detection machines?

Helium leak detection machines are highly accurate, capable of detecting very small leaks that other methods may miss.

3. Can helium leak detection be used for all packaging types?

Yes, helium leak detection can be used on various packaging materials, including plastics, metals, and composites.

4. Is helium leak detection environmentally friendly?

Yes, helium is a non-toxic and inert gas, making it a safe option for leak detection.

5. How often should helium leak detection machines be calibrated?

It is recommended to calibrate helium leak detection machines regularly, typically on a monthly basis or as per the manufacturer's guidelines.

Conclusion

Integrated helium leak detection machines are revolutionizing the packaging testing industry by offering unparalleled accuracy, efficiency, and versatility. As technology continues to evolve, these systems are becoming an essential standard in maintaining product integrity across various sectors. By adopting helium leak detection, manufacturers can ensure their products meet the highest quality and safety standards, ultimately leading to enhanced consumer trust and satisfaction. Embracing this innovative technology is not just a trend; it's a significant step toward a future of reliable packaging solutions.

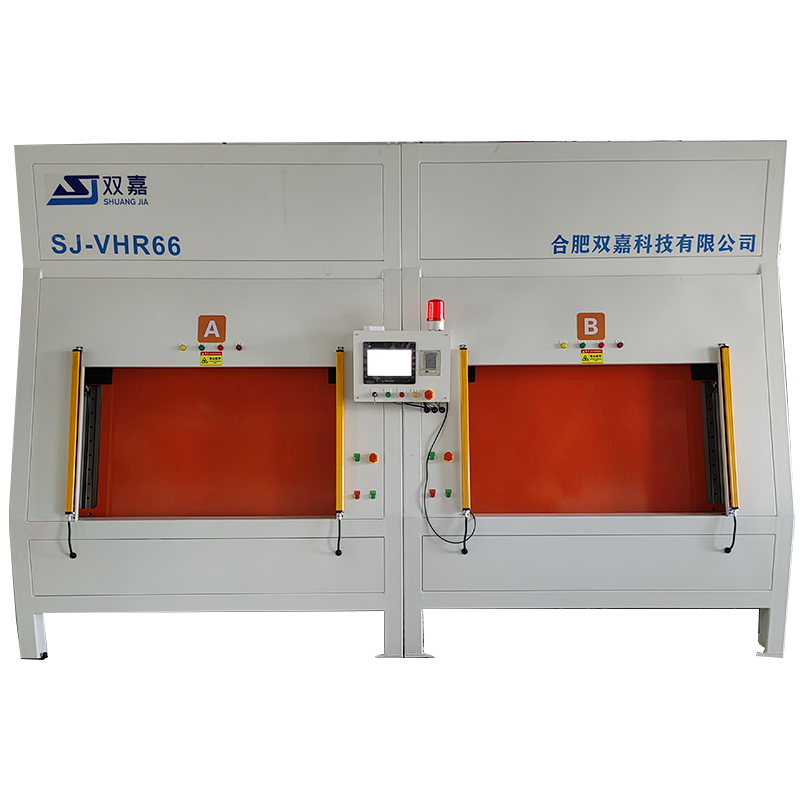

Integrated helium leak detection machine

Previous Page

Previous Page

Latest Blog