Information Details

Issues to Note When Using a Helium Leak Detector with the Suction Gun Method

Helium leak detection using a suction gun (positive pressure method). When using pure helium, a helium recovery device can be used for reuse to reduce costs. Alternatively, a helium gas mixture with a concentration of no less than 5-10% can be used and directly discharged into the atmosphere after use. Pay attention to the concentration of helium in the surrounding environment and the airflow, as this will affect the detection accuracy of the suction gun method.

Release time:

2025-03-11

Helium leak detection using the suction gun method (positive pressure method): When using pure helium for leak detection, a helium recovery device can be used for reuse to reduce costs. Alternatively, a helium gas mixture with a concentration of no less than 5-10% can be used, and after use, it can be directly discharged into the atmosphere. Pay attention to the concentration of helium in the surrounding environment and the airflow in the surrounding environment, as this will affect the detection accuracy of the suction gun method.

The suction gun method (positive pressure method) leak detection is very similar to halogen leak detection, but it should be noted that the tracer gas filled in the container is different. Even with the same leak rate value, the meaning is different, and it is important to be able to distinguish this. In addition to the experimental test comparison method, there are also formulas Q1η1=Q2η2 (Q is the gas leakage flow rate, η is the gas viscosity coefficient), Q1M11/2=Q2M21/2 (M is the molecular weight of the gas).

The following points should be noted when using a helium leak detector for leak detection with the suction gun method:

1. Sensitivity is limited by the conductance of the connecting pipeline.

2. When performing the initial leak detection, do not introduce excessively high pressure helium into the inspected object. Because if there is a leak hole, helium will leak out of the inspected object, causing significant waste, and the helium will diffuse everywhere, causing great interference to the leak detector. Therefore, generally, low-pressure, low-concentration helium should be introduced into the inspected object first, and then high-pressure, high-concentration helium should be introduced for leak detection of small leak holes. If there are large leak holes, the pressure-holding water bubbling method can be used to detect large leaks first, which can reduce helium waste, as helium is expensive (the Price varies with concentration), and prevent damage to the helium leak detector due to helium poisoning.

(3) Helium Hood Method

This method uses a leak detection hood (plastic film, etc.) to enclose the container being inspected. First, the air inside the hood is removed, and then helium or a helium mixture is introduced. The leak detector is connected to the interior of the container being inspected. When the leak detector shows a leak rate, it indicates a leak. This leak rate is called the total leak rate. The total leak rate is the sum of the individual leak rates; if the total leak rate does not exceed the standard value, then the individual leak rates will not exceed the standard value either; if the total leak rate exceeds the standard value, then check whether the individual leak rates at each point exceed the standard value. Then repair the leak holes that exceed the standard value until the qualified standard is met.

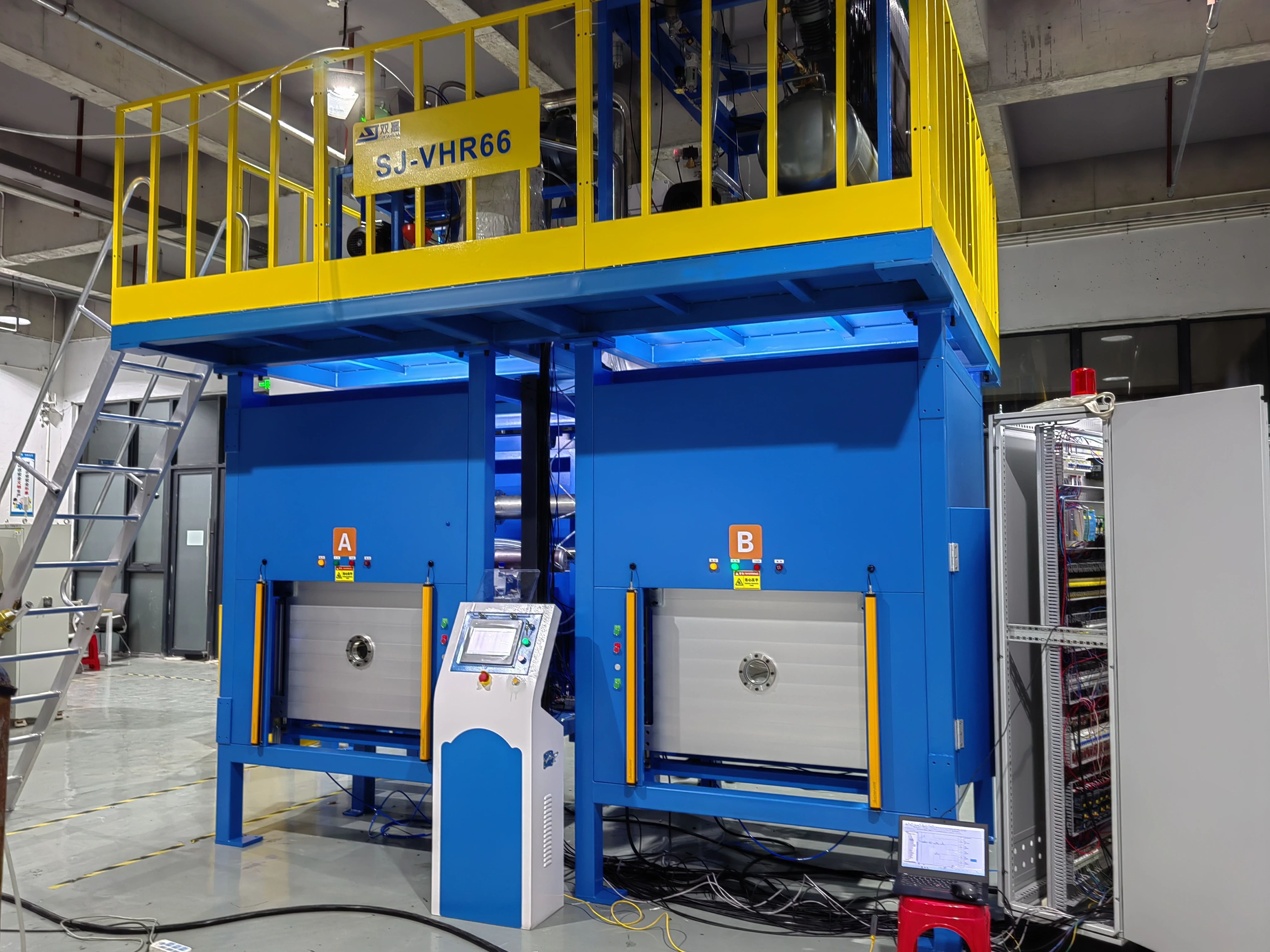

When detecting leaks in large pressure vessels, an auxiliary vacuum system (auxiliary vacuum system - consisting of a vacuum mechanical pump + booster pump, vacuum pipeline, three-way valve, vacuum gauge, vacuum valve, and exhaust valve, etc.) is often used for pre-vacuuming. When the vacuum degree reaches a certain value, the auxiliary vacuum system is closed, or a vacuum switching valve is used, and then the helium leak detector is turned on for leak detection.

Anhui Bowie Optoelectronics Technology Co., Ltd. is a professional supplier specializing in the research and development, production, and sales of helium leak detection technology. In order to develop helium leak detection equipment that truly meets the needs of enterprises, the company closely follows the technical and industry development characteristics of helium leak detection, continuously optimizes industry technology, and strictly adheres to national and industry standards throughout the entire process of product research and development, design and manufacturing, and selection. At the same time, the equipment has high compatibility and maintainability for upgrades, modular manufacturing, and standardized processes, which can ensure a start-up rate of over 98% for 10 years, providing customers with the best quality service and investment return.

Latest Blog