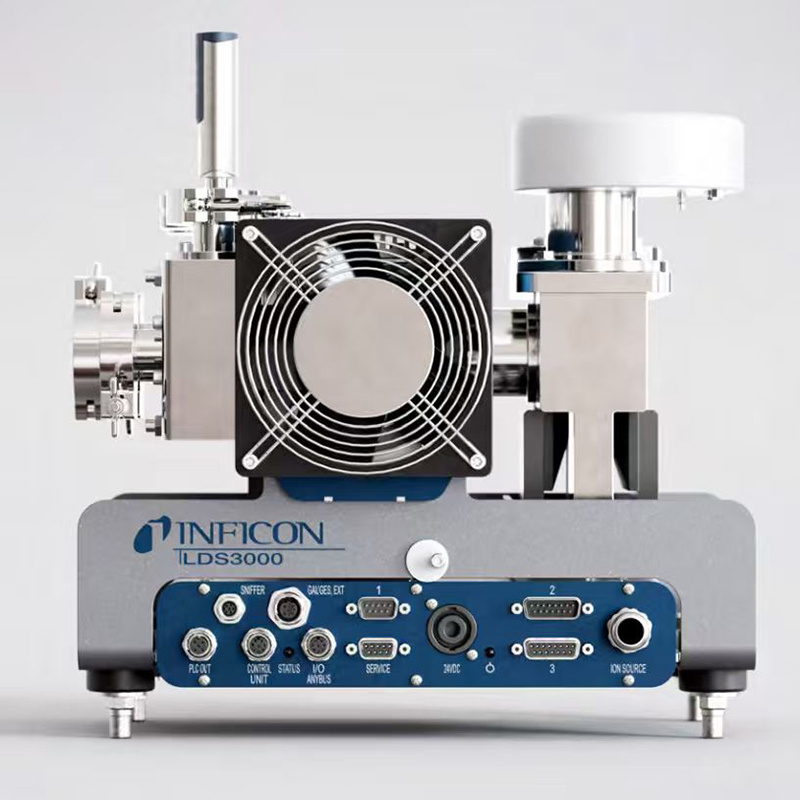

Helium Leak Detector

Classification:

Key words:

Helium Leak Detector

Product Details

Our leak detectors can be used to pinpoint leak locations, while some are better suited for determining the overall leakage rate of the test object.

Whether a component or system is sealed depends on its intended application and the acceptable leakage rate. Absolutely sealed components and systems simply do not exist. However, if a component’s leakage rate remains below the value defined for that specific component, it is technically considered leak-free.

In addition to ensuring overall sealing performance, it is often crucial to quickly and accurately locate leak points when sealing systems or components. Instruments used for localized leak detection are called leak detectors.

In practice, a leak-testing instrument first evacuates the object being tested to create a pressure differential, allowing external gases to be drawn in through any existing leakage points. Alternatively, if helium gas is simply directed toward the suspected leak location—such as by using a spray gun—the helium will flow through the leak and be extracted by the leak detector. The partial helium pressure within the detector is then measured by a mass spectrometer and displayed as the leak rate, typically reported in terms of helium volumetric flow (pV-flow).

Advantages

Oil-free pump system—powered by Leybold's reliable SCROLLVAC 3 Plus pump

Fast, reliable, and highly sensitive testing

The maximum pressure is relatively low.

Outstanding pumping speed—more tests per hour, leading to faster detection rates.

Quickly recover after exposure to helium

The only advanced dry-type leak detector on the market that doesn't contain a diaphragm pump.

Improved zeroing functionality

Previous:

Previous:

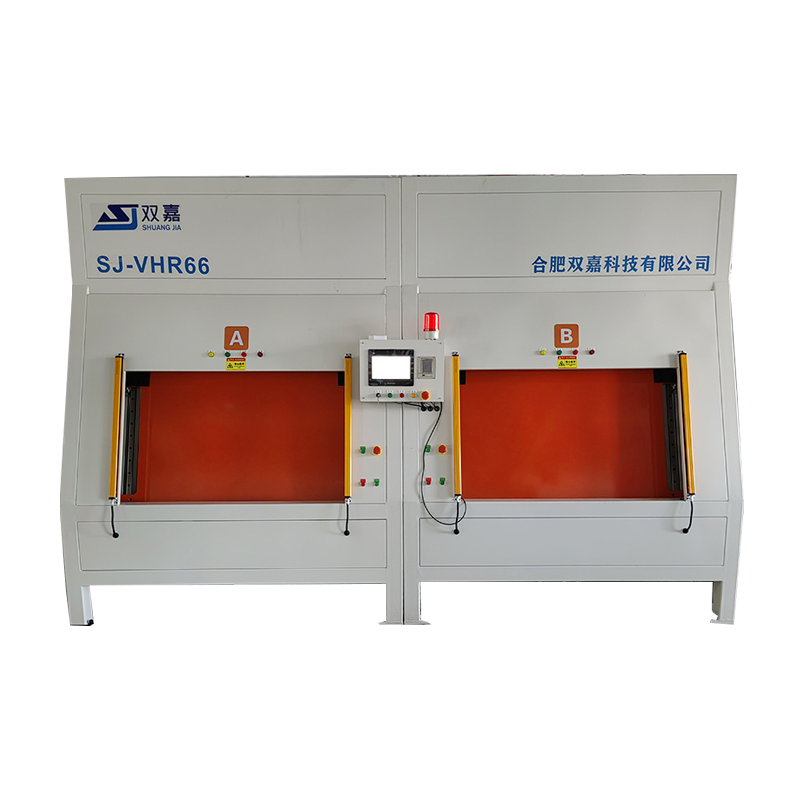

Related Products

Product Consulting

Welcome to leave us a message, we will contact us as soon as possible!