Integrated vacuum box helium leak detection and recovery equipment

Key words:

Integrated vacuum box helium leak detection and recovery equipment

Product Details

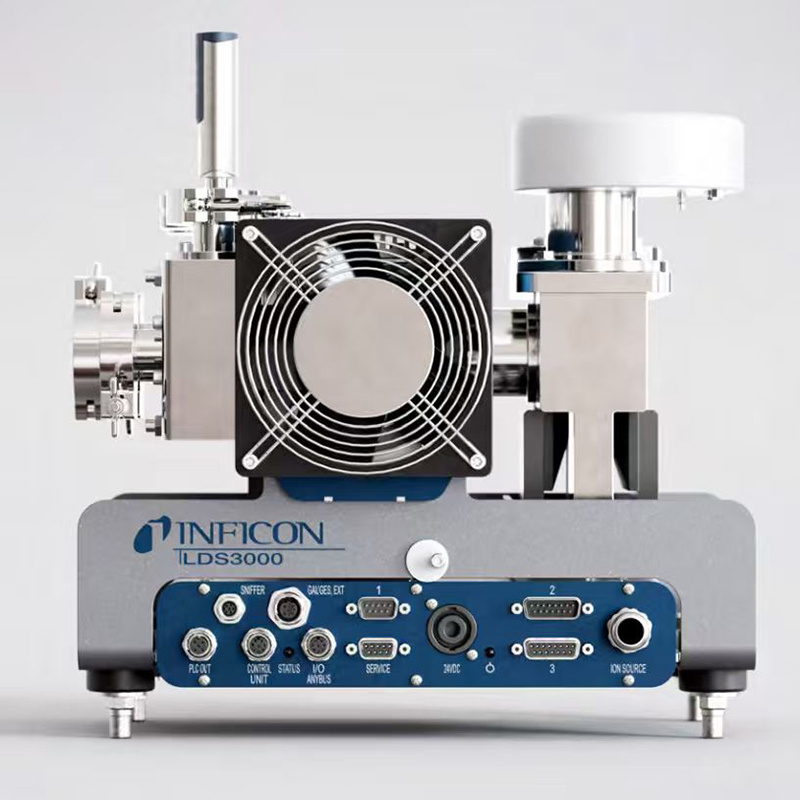

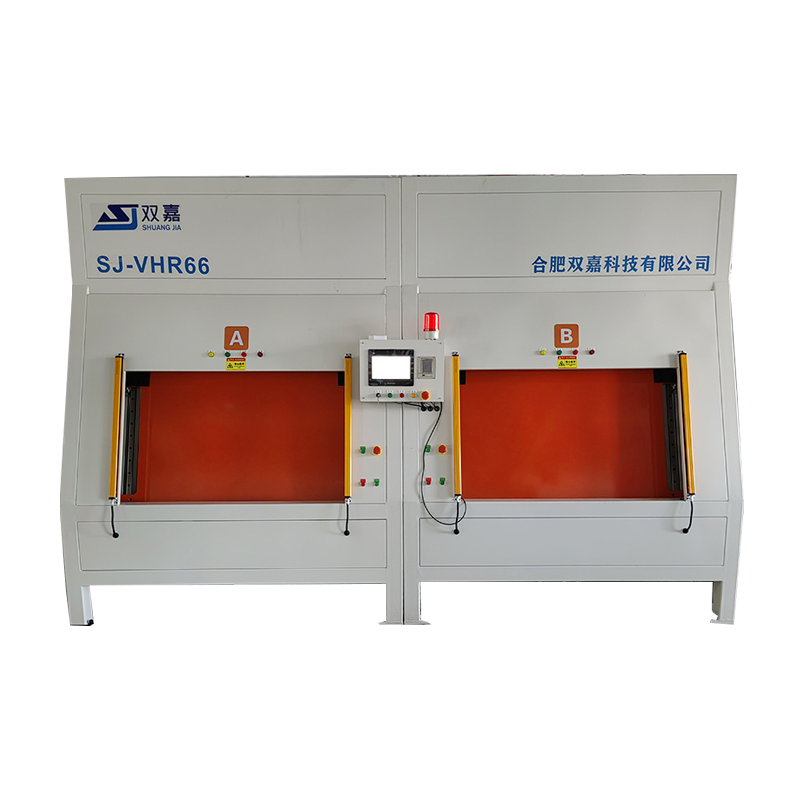

Device Introduction:This equipment can perform dry, non-destructive helium leak detection on die-cast parts for new energy vehicles. It uses a vacuum chamber method to evacuate the vacuum chamber, ensuring that the product is not affected by external interference. Helium gas is injected into the product at a certain pressure, and a helium mass spectrometer leak detector is used to test the product for helium leaks. The vacuum pressure in the vacuum chamber is less than 20Pa, and the leak detection accuracy can reach 5.0E-9Pa·m³/s.

Main Technical Parameters

1. Operation Method: Manual loading to the designated position, automatic gripping by the robotic arm and placement into the vacuum chamber

2. Vacuum Chamber Volume: <10ml

3. Number of Vacuum Chambers: 5 (2 sets)

4. Number of Products Tested per Chamber: 1

5. Helium Filling Pressure: 0.1MPa-0.2MPa

6. Testing Cycle: Single set ≤60s (excluding manual operation time), dual set linkage ≤30s; 6s per test

7. Detection Accuracy: ≤5.0E-9Pa·m³/s

8. The vacuum chamber uses a quick-change method, making it convenient to test different product models

9. Fully automatic detection process, simple operation

10. Human-machine interaction interface for easy maintenance

11. With data storage function, detection data can be traced

Related Products

Product Consulting

Welcome to leave us a message, we will contact us as soon as possible!