Information Details

Discover How Helium Tracer Leak Detection Systems are Transforming Non-Destructive Testing

Discover How Helium Tracer Leak Detection Systems are Transforming Non-Destructive Testing Table of Contents 1. Introduction to Non-Destructive Testing 2. What is Helium Tracer Leak Detection? 3. Advantages of Helium Tracer Leak Detection Systems 4. Key Applications of Helium Leak Detection Systems 5. How Helium Leak Detection Works 6. Comparing Helium Leak Detection to Ot

Release time:

2025-04-29

Discover How Helium Tracer Leak Detection Systems are Transforming Non-Destructive Testing

Table of Contents

- 1. Introduction to Non-Destructive Testing

- 2. What is Helium Tracer Leak Detection?

- 3. Advantages of Helium Tracer Leak Detection Systems

- 4. Key Applications of Helium Leak Detection Systems

- 5. How Helium Leak Detection Works

- 6. Comparing Helium Leak Detection to Other Methods

- 7. The Future of Helium Tracer Leak Detection Systems

- 8. Conclusion

- 9. FAQs about Helium Tracer Leak Detection

1. Introduction to Non-Destructive Testing

Non-destructive testing (NDT) is a vital process in various industries, including aerospace, automotive, manufacturing, and oil and gas. It enables engineers and quality assurance professionals to evaluate the integrity of materials and components without causing any damage. By identifying defects, leaks, and weaknesses early in the production process, NDT helps maintain safety and reliability.

One of the most significant advancements in NDT technology is the development of helium tracer leak detection systems. These systems offer unparalleled sensitivity and accuracy in identifying leaks, making them an essential tool in the quality control arsenal.

2. What is Helium Tracer Leak Detection?

Helium tracer leak detection involves using helium gas as a tracer to identify leaks in sealed systems. Helium is an inert, non-toxic gas that, due to its small atomic size, can easily penetrate even the tiniest openings. When helium is introduced into a system, an appropriate detector can sense its presence, allowing for precise identification of leaks.

This method has gained prominence because of its efficiency and reliability, especially in critical applications where even minute leaks can lead to catastrophic failures.

3. Advantages of Helium Tracer Leak Detection Systems

Helium tracer leak detection systems offer numerous advantages that enhance their effectiveness in non-destructive testing:

3.1 Extreme Sensitivity

Helium leak detectors can identify leaks as small as 1 x 10^-12 mbar L/s, making them one of the most sensitive leak detection methods available. This extreme sensitivity is crucial in industries where even tiny leaks can lead to significant safety concerns.

3.2 Fast and Accurate Results

The speed at which helium leak detection systems operate enables rapid assessments. The immediate feedback provided by these systems reduces downtime and accelerates the quality control process.

3.3 Versatility

Helium tracer leak detection is applicable across various industries, including aerospace, medical devices, and automotive manufacturing. It is effective for testing various components, from fuel tanks to vacuum systems.

3.4 Non-Damaging Testing Method

As a non-destructive testing method, helium leak detection does not harm the components being tested. This feature is essential for preserving the integrity of expensive or critical parts.

3.5 Environmentally Friendly

Helium is a non-toxic and environmentally friendly gas, making it a safe choice for leak detection compared to other methods that may utilize harmful substances.

4. Key Applications of Helium Leak Detection Systems

Helium tracer leak detection systems are utilized in various industries for multiple applications:

4.1 Aerospace Industry

In the aerospace sector, the integrity of fuel systems, pressurized cabins, and life support systems is paramount. Helium leak detection ensures that these systems function correctly, safeguarding both equipment and personnel.

4.2 Automotive Manufacturing

The automotive industry employs helium leak detection to test fuel tanks, air conditioning systems, and engine components. By ensuring airtight seals, manufacturers enhance vehicle performance and safety.

4.3 Medical Device Production

Medical devices often require stringent leak testing to ensure patient safety. Helium tracer leak detection is used to validate the integrity of devices such as syringes, IV bags, and surgical equipment.

4.4 Oil and Gas Industry

In the oil and gas sector, helium leak detection systems play a crucial role in maintaining the integrity of pipelines, storage tanks, and drilling equipment, preventing leaks that could have catastrophic environmental consequences.

4.5 Electronics Manufacturing

Electronics, particularly those that operate in high-vacuum environments, benefit from helium leak detection. Ensuring that products are leak-tight is essential to maintain performance and reliability.

5. How Helium Leak Detection Works

Understanding how helium leak detection works is essential to appreciate its role in non-destructive testing. The process involves several key steps:

5.1 Preparing the Test Item

The component or system needing testing is sealed and prepared for the leak detection process. This may involve isolating the area to be tested and ensuring that it is free from contaminants.

5.2 Introducing Helium

Once the test item is ready, helium gas is introduced into the system. This can be done by filling the entire vessel with helium or by using a vacuum chamber to create a controlled environment.

5.3 Detecting Leaks

Specialized helium leak detectors are then employed to scan the exterior of the test item. These detectors are highly sensitive and can detect the presence of helium in the environment surrounding the component, indicating the location and size of any leaks.

5.4 Analyzing Results

Data collected during the detection process is analyzed to determine the presence, size, and location of any leaks. This information is crucial for making informed decisions about repairs or further testing.

6. Comparing Helium Leak Detection to Other Methods

When evaluating leak detection methods, it is essential to consider the advantages and disadvantages of each. Here, we compare helium leak detection with several other common techniques:

6.1 Bubble Testing

Bubble testing involves applying a soap solution to the surface of the component and observing for bubbles. While simple and cost-effective, this method lacks the sensitivity of helium leak detection and may not identify small leaks effectively.

6.2 Pressure Decay Testing

Pressure decay testing measures the drop in pressure within a sealed system over time. While useful, it can be less accurate than helium detection, particularly in identifying small leaks.

6.4 Tracer Gas Testing

Other tracer gases, such as hydrogen or nitrogen, can also be used. However, helium's inert properties and smaller atomic size often make it a superior choice for sensitivity and reliability.

7. The Future of Helium Tracer Leak Detection Systems

The future of helium tracer leak detection systems looks promising, with ongoing advancements in technology. Developments in detector sensitivity, automation, and data analysis are expected to enhance the capabilities of these systems further.

7.1 Integration with Digital Technologies

The integration of helium leak detection systems with digital technologies, such as IoT and AI, is anticipated to revolutionize NDT. Smart sensors and real-time data analysis will enable predictive maintenance and proactive leak management.

7.2 Increased Adoption Across Industries

As industries continue to prioritize safety and quality assurance, the adoption of helium tracer leak detection systems will likely increase. This trend will drive innovation and lead to improved testing methodologies.

8. Conclusion

Helium tracer leak detection systems are transforming the landscape of non-destructive testing by providing unparalleled sensitivity, speed, and reliability. Their applications span numerous industries, ensuring the integrity of critical systems while promoting safety and efficiency. As technology advances, we can expect helium leak detection methods to become even more sophisticated, solidifying their role as a cornerstone in the quality assurance process.

9. FAQs about Helium Tracer Leak Detection

What is the primary advantage of using helium for leak detection?

The primary advantage of using helium for leak detection is its extreme sensitivity, allowing for the identification of leaks as small as 1 x 10^-12 mbar L/s.

Is helium leak detection safe?

Yes, helium is a non-toxic and inert gas, making it a safe choice for leak detection.

How long does the helium leak detection process take?

The helium leak detection process is typically fast, providing results within minutes, depending on the complexity of the test item.

Can helium leak detection be automated?

Yes, advancements in technology allow for the automation of helium leak detection systems, improving efficiency and accuracy.

What industries benefit the most from helium tracer leak detection systems?

Industries such as aerospace, automotive, medical devices, oil and gas, and electronics manufacturing benefit significantly from helium tracer leak detection systems due to their stringent quality assurance requirements.

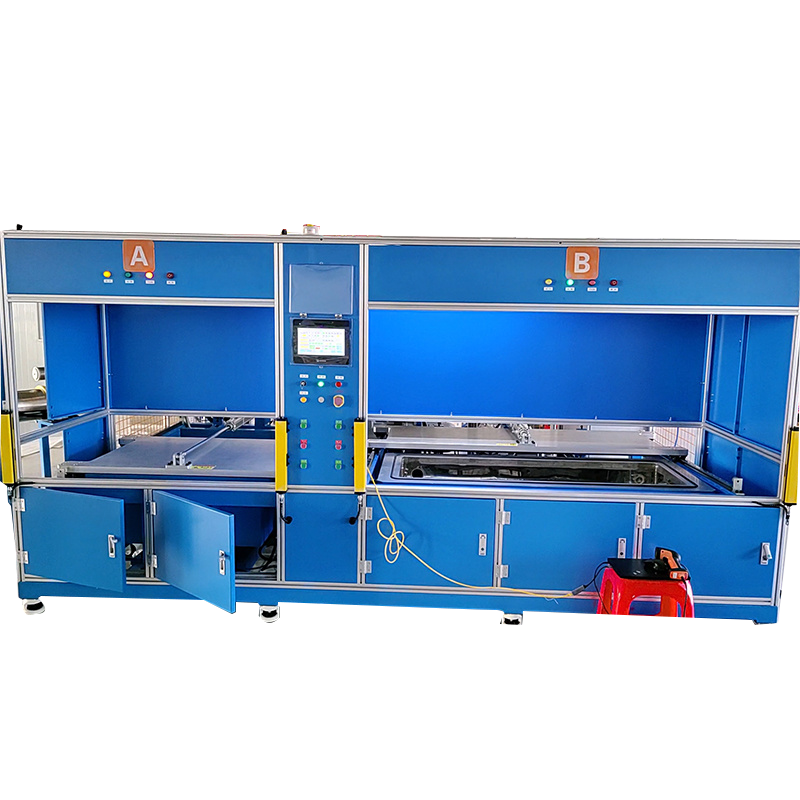

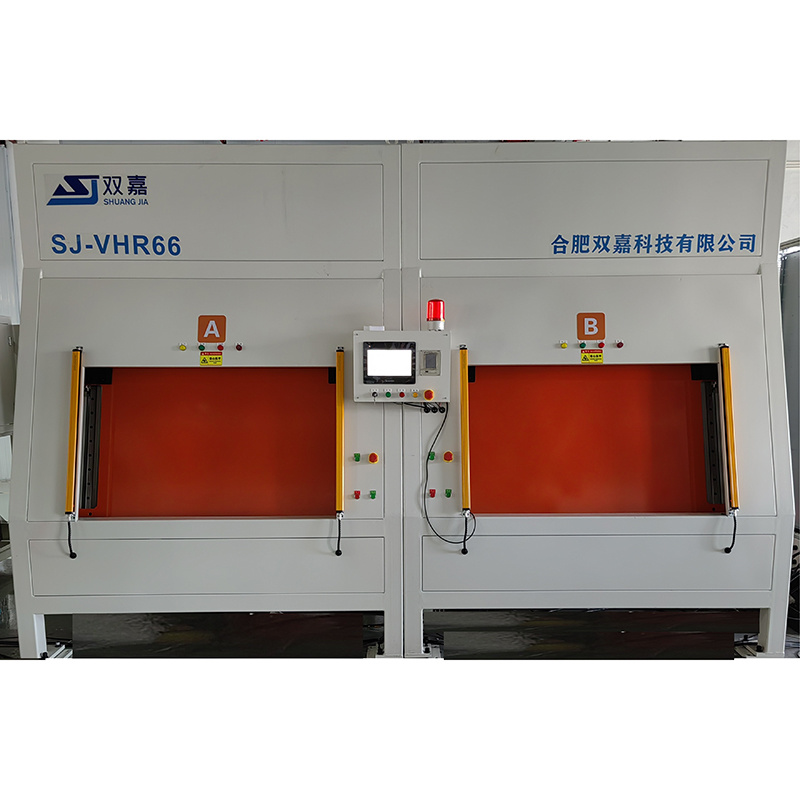

Helium tracer leak detection system

Latest Blog