Information Details

Understanding Helium Leak Detection in Battery Packs: A Key to Reliability

Helium leak detection for battery packs is a sophisticated and effective technique used to identify and quantify leaks in sealed systems. As the demand for high-performance batteries continues to grow, particularly in electric vehicles and portable electronics, the need for reliable leak detection methods has become increasingly crucial. The integrity of battery packs is essential not only for per

Release time:

2025-05-02

Helium leak detection for battery packs is a sophisticated and effective technique used to identify and quantify leaks in sealed systems. As the demand for high-performance batteries continues to grow, particularly in electric vehicles and portable electronics, the need for reliable leak detection methods has become increasingly crucial. The integrity of battery packs is essential not only for performance but also for safety, as leaks can lead to catastrophic failures.

Helium, a noble gas, is often employed in leak detection due to its unique properties. It is non-toxic, non-flammable, and has a small atomic size, allowing it to penetrate even the tiniest of leaks. Utilizing helium as a tracer gas enables technicians to detect leaks that might be missed by other methods. This capability is particularly important in battery packs, where even minor leaks can compromise the overall performance of the battery.

The process of helium leak detection typically involves charging the battery pack with helium and then performing a vacuum test. The battery is placed in a vacuum chamber, and any escaping helium is detected using a sensitive mass spectrometer. This method not only identifies the location of the leak but also provides valuable data about its size and severity. By identifying leaks early in the manufacturing process, companies can prevent potential failures and reduce the risk of warranty claims.

Moreover, helium leak detection plays a significant role in maintaining the longevity of battery packs. Regular testing can help identify issues before they escalate, ensuring that batteries operate efficiently throughout their intended lifespan. This proactive approach not only enhances customer satisfaction but also mitigates risks associated with battery failures, such as thermal runaway or reduced capacity.

In conclusion, helium leak detection for battery packs is a critical aspect of quality control in the battery industry. By adopting this advanced leak detection method, companies can improve product reliability, enhance safety, and maintain consumer trust. As technology continues to advance, integrating helium leak detection into standard manufacturing practices will become increasingly essential for staying competitive and meeting the rigorous demands of today’s energy market. Emphasizing the importance of leak detection can lead to safer, more efficient battery solutions that meet the needs of consumers and industries alike.

Helium, a noble gas, is often employed in leak detection due to its unique properties. It is non-toxic, non-flammable, and has a small atomic size, allowing it to penetrate even the tiniest of leaks. Utilizing helium as a tracer gas enables technicians to detect leaks that might be missed by other methods. This capability is particularly important in battery packs, where even minor leaks can compromise the overall performance of the battery.

The process of helium leak detection typically involves charging the battery pack with helium and then performing a vacuum test. The battery is placed in a vacuum chamber, and any escaping helium is detected using a sensitive mass spectrometer. This method not only identifies the location of the leak but also provides valuable data about its size and severity. By identifying leaks early in the manufacturing process, companies can prevent potential failures and reduce the risk of warranty claims.

Moreover, helium leak detection plays a significant role in maintaining the longevity of battery packs. Regular testing can help identify issues before they escalate, ensuring that batteries operate efficiently throughout their intended lifespan. This proactive approach not only enhances customer satisfaction but also mitigates risks associated with battery failures, such as thermal runaway or reduced capacity.

In conclusion, helium leak detection for battery packs is a critical aspect of quality control in the battery industry. By adopting this advanced leak detection method, companies can improve product reliability, enhance safety, and maintain consumer trust. As technology continues to advance, integrating helium leak detection into standard manufacturing practices will become increasingly essential for staying competitive and meeting the rigorous demands of today’s energy market. Emphasizing the importance of leak detection can lead to safer, more efficient battery solutions that meet the needs of consumers and industries alike.

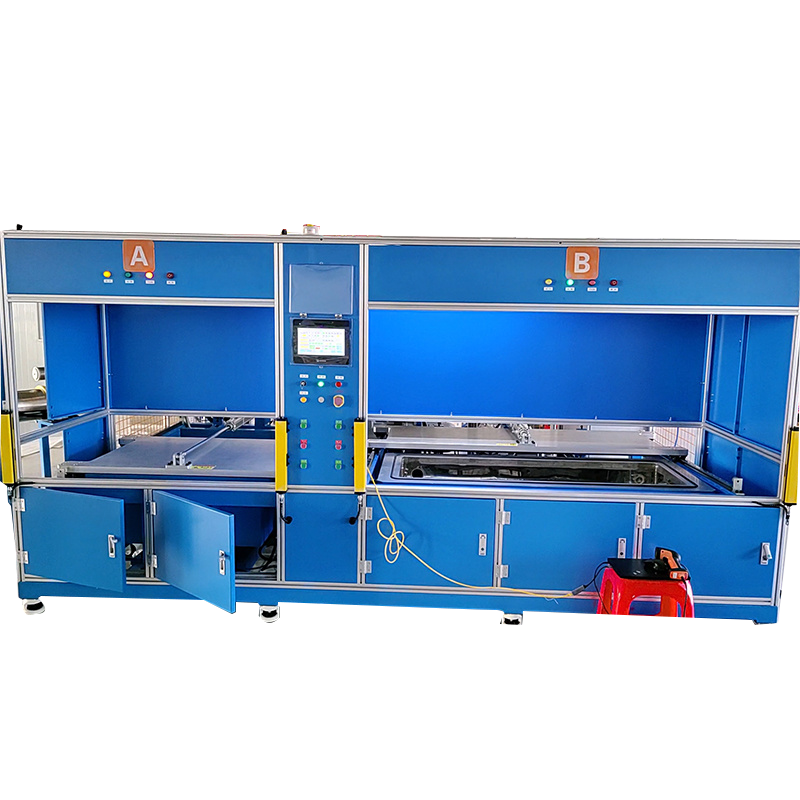

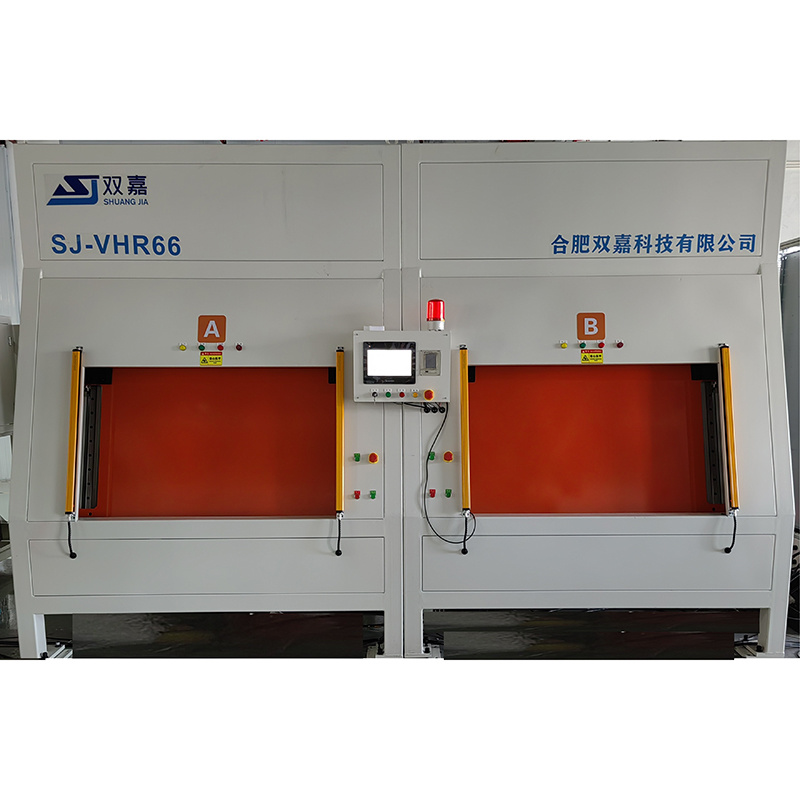

Helium leak detection for battery packs

Previous Page

Previous Page

Latest Blog