Information Details

The Essential Guide to Integrated Helium Leak Detection Machines

In the realm of packaging testing equipment, the integrated helium leak detection machine stands out as a pivotal tool for ensuring the quality and integrity of various products. These machines are widely used across several industries, including pharmaceuticals, electronics, automotive, and more, where maintaining a leak-free environment is crucial. The basic principle behind helium leak detecti

Release time:

2025-08-22

In the realm of packaging testing equipment, the integrated helium leak detection machine stands out as a pivotal tool for ensuring the quality and integrity of various products. These machines are widely used across several industries, including pharmaceuticals, electronics, automotive, and more, where maintaining a leak-free environment is crucial.

The basic principle behind helium leak detection is straightforward: helium is a small, light molecule that can easily escape through microscopic leaks in packaging. When using an integrated helium leak detection machine, helium is introduced into the package or system being tested. The machine then measures the concentration of helium that escapes, allowing technicians to identify and quantify leaks effectively.

One of the main advantages of integrated helium leak detection machines is their precision. Unlike other leak detection methods, such as bubble tests or pressure decay tests, helium leak detection provides a more accurate and sensitive approach. This sensitivity is particularly important in industries like pharmaceuticals, where even the smallest breach can lead to contamination or a loss of product efficacy.

Furthermore, these machines are designed for integration into production lines, enhancing efficiency and reducing the time taken for leak testing. By incorporating the detection system directly into the packaging process, manufacturers can quickly assess the quality of their products without significant downtime. This integration not only streamlines operations but also contributes to a reduction in overall production costs.

Another key advantage is the non-destructive nature of helium leak detection. Since the method does not compromise the integrity of the product being tested, it allows for thorough quality assurance without the risk of damage. This is particularly advantageous in high-value industries, where preserving product integrity is paramount.

Moreover, the use of helium as a tracer gas is environmentally friendly. Helium is non-toxic and does not pose any risks to users or the environment, making it a preferred choice for many manufacturers committed to sustainability.

As technology continues to advance, modern integrated helium leak detection machines have become more user-friendly, featuring intuitive interfaces and advanced data analysis capabilities. This evolution allows operators to quickly interpret results and make informed decisions, enhancing the overall efficiency of the testing process.

In conclusion, integrated helium leak detection machines are indispensable in ensuring product quality and reliability across various industries. Their precision, efficiency, and non-destructive testing capabilities make them the preferred choice for manufacturers, contributing significantly to quality assurance practices. Investing in such technology not only enhances product integrity but also reinforces a company's commitment to excellence in production.

The basic principle behind helium leak detection is straightforward: helium is a small, light molecule that can easily escape through microscopic leaks in packaging. When using an integrated helium leak detection machine, helium is introduced into the package or system being tested. The machine then measures the concentration of helium that escapes, allowing technicians to identify and quantify leaks effectively.

One of the main advantages of integrated helium leak detection machines is their precision. Unlike other leak detection methods, such as bubble tests or pressure decay tests, helium leak detection provides a more accurate and sensitive approach. This sensitivity is particularly important in industries like pharmaceuticals, where even the smallest breach can lead to contamination or a loss of product efficacy.

Furthermore, these machines are designed for integration into production lines, enhancing efficiency and reducing the time taken for leak testing. By incorporating the detection system directly into the packaging process, manufacturers can quickly assess the quality of their products without significant downtime. This integration not only streamlines operations but also contributes to a reduction in overall production costs.

Another key advantage is the non-destructive nature of helium leak detection. Since the method does not compromise the integrity of the product being tested, it allows for thorough quality assurance without the risk of damage. This is particularly advantageous in high-value industries, where preserving product integrity is paramount.

Moreover, the use of helium as a tracer gas is environmentally friendly. Helium is non-toxic and does not pose any risks to users or the environment, making it a preferred choice for many manufacturers committed to sustainability.

As technology continues to advance, modern integrated helium leak detection machines have become more user-friendly, featuring intuitive interfaces and advanced data analysis capabilities. This evolution allows operators to quickly interpret results and make informed decisions, enhancing the overall efficiency of the testing process.

In conclusion, integrated helium leak detection machines are indispensable in ensuring product quality and reliability across various industries. Their precision, efficiency, and non-destructive testing capabilities make them the preferred choice for manufacturers, contributing significantly to quality assurance practices. Investing in such technology not only enhances product integrity but also reinforces a company's commitment to excellence in production.

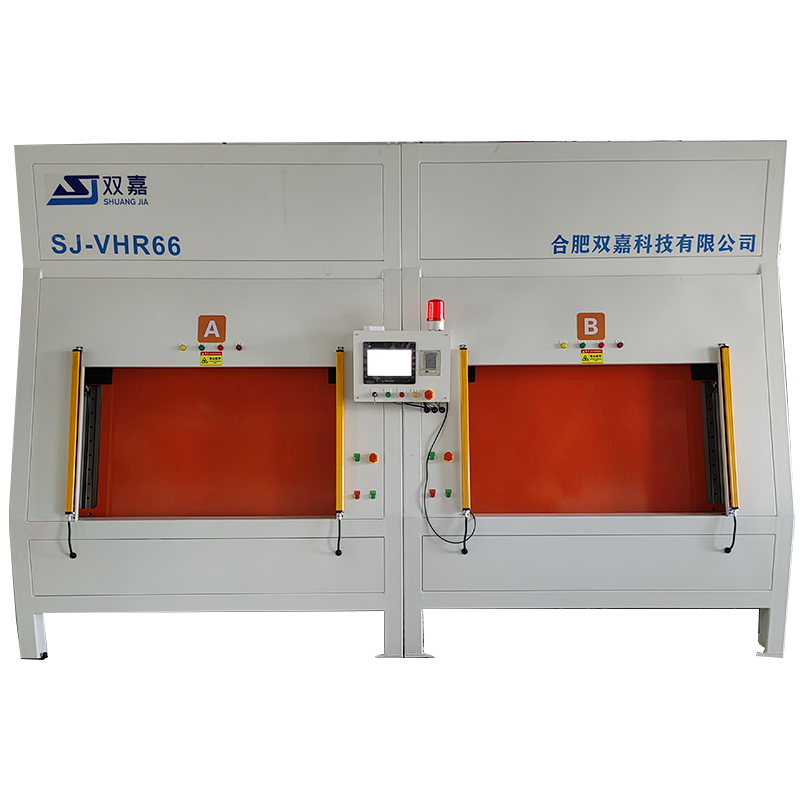

Integrated helium leak detection machine

Previous Page

Previous Page

Latest Blog