Integrated vacuum box helium leak detection and recovery equipment

Key words:

Integrated vacuum box helium leak detection and recovery equipment

Product Details

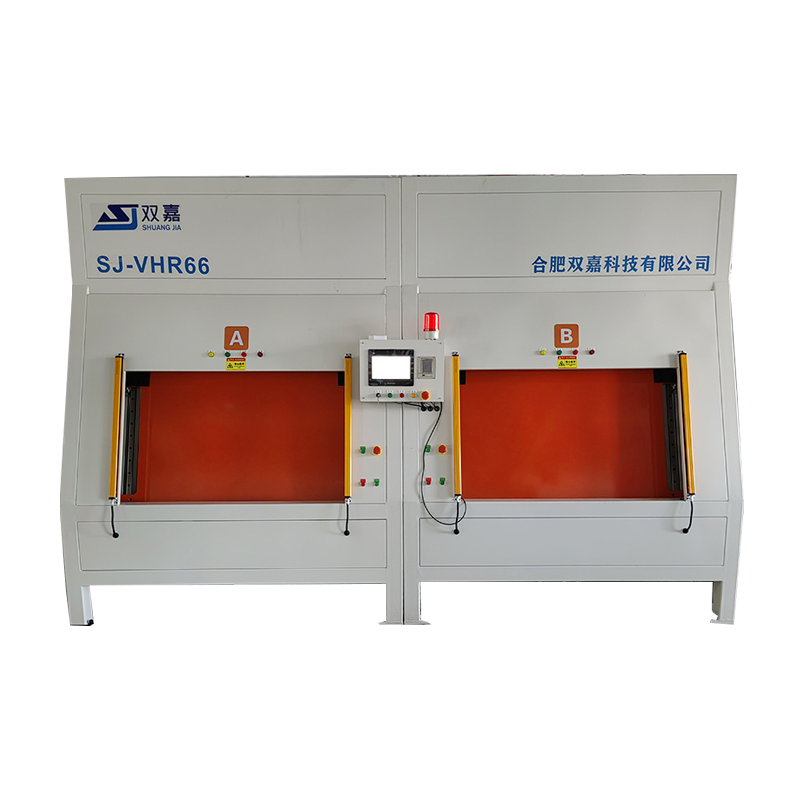

Device Introduction

This equipment can perform dry, non-destructive helium leak detection on water-cooled plates and condensers. Utilizing the unique physical properties of helium, the vacuum chamber method is employed with the vacuum chamber evacuated to ensure the product is not affected by external interference. A certain pressure of helium gas is introduced into the product, and a helium mass spectrometer leak detector is used to test for helium leaks. The vacuum pressure in the chamber is less than 20Pa, and the leak detection accuracy can reach 1.0E-8Pa·m³/s.

Main Technical Parameters

1. Operating Method: Single-box sliding door, manual loading and unloading (in-chamber inspection)

2. Vacuum Chamber Volume: Length 800 * Width 400 * Depth 250, 80L

3. Number of Products Tested per Chamber: 2

4. Helium Filling Pressure: 0.3MPa-1.5MPa

5. Detection Cycle: 60s/chamber

6. Detection Accuracy: ≤1.0E-8Pa·m³/s

7. Fully automatic detection process, easy operation

8. Human-machine interface, convenient maintenance

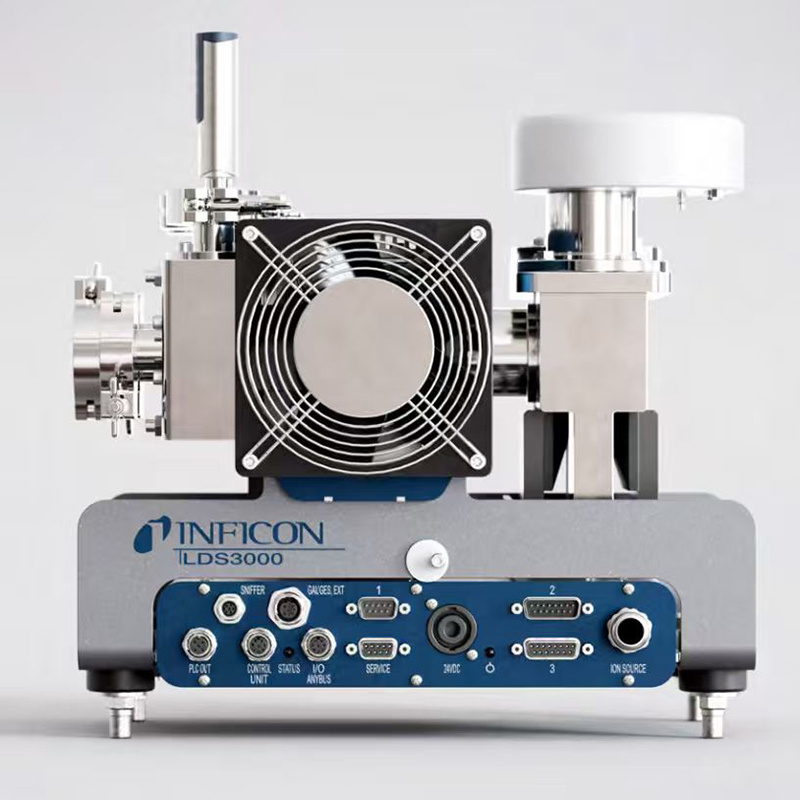

Our Helium Detection and Purification Unit is a cutting-edge solution designed to efficiently identify and purify helium in various industrial applications. This unit is ideal for industries such as medical, aerospace, and research, where helium plays a critical role in processes like MRI scans, cryogenics, and scientific experiments. Equipped with advanced sensors and filtration systems, the Helium Detection and Purification Unit ensures accurate detection and removal of impurities, maintaining high helium purity levels.

The Helium Detection and Purification Unit operates with precision, providing real-time monitoring and purification of helium gas. Its innovative design includes both detection and purification mechanisms, ensuring that the helium used in your processes is free from contaminants. The unit is highly efficient, reducing helium loss and improving the overall quality of the gas for sensitive operations. It is also easy to operate, with intuitive controls and minimal maintenance requirements.

With its robust construction and high-performance capabilities, the Helium Detection and Purification Unit is designed to work in demanding environments, delivering consistent results. Whether you are working in a laboratory, medical facility, or industrial setting, this unit provides a reliable and cost-effective solution for helium purification and detection. Trust our Helium Detection and Purification Unit to enhance your helium usage and ensure the highest standards of quality and safety.

Related Products

Product Consulting

Welcome to leave us a message, we will contact us as soon as possible!