Integrated vacuum box helium leak detection and recovery equipment

Key words:

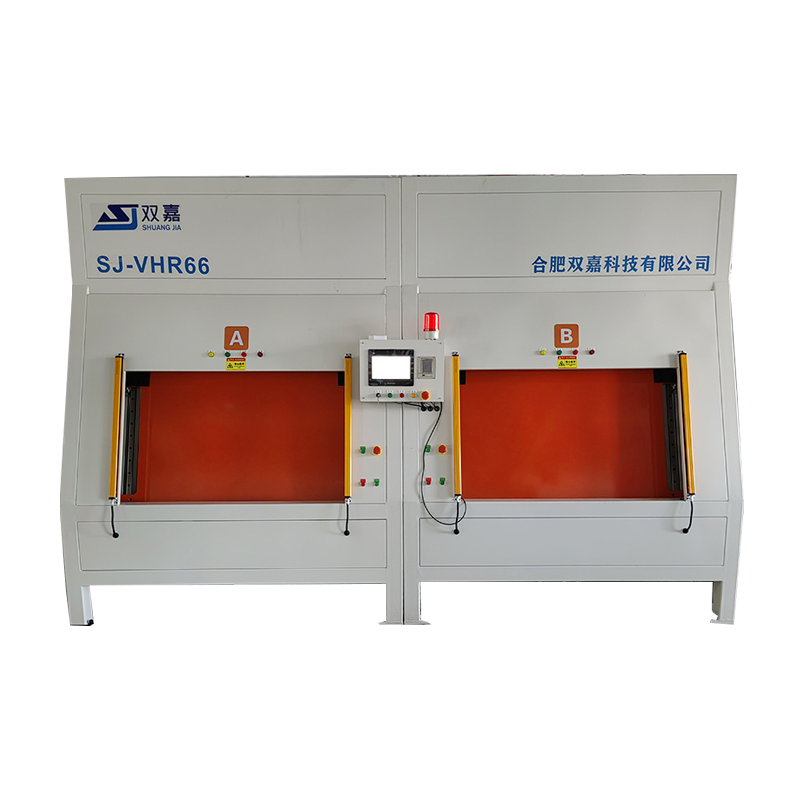

Integrated vacuum box helium leak detection and recovery equipment

Product Details

Equipment Introduction

This equipment can perform dry, non-destructive helium leak detection on the two components of household air conditioners. Utilizing the unique physical properties of helium gas, a vacuum chamber method is employed to evacuate the vacuum chamber, ensuring the product is not affected by external interference. Helium gas is injected into the product at a certain pressure, and a helium mass spectrometer leak detector is used to test for helium leaks in the product. The vacuum pressure in the vacuum chamber is less than 20Pa, and the leak detection accuracy can reach 5.0E-7Pa·m³/s.

Main Technical Parameters

1. Operation Method: Four-chamber sliding door, tunnel type, the tested product enters and exits the vacuum chamber with the production line (external box inspection)

2. Vacuum Chamber Volume: 800mm wide * 1500mm high * 800mm deep, 960L

3. Number of Products Tested per Chamber: 2

4. Helium Filling Pressure: 1.0MPa-1.5MPa

5. Detection Cycle: 120s/chamber for a single chamber, 30s/chamber for four chambers linked

6. Detection Accuracy: ≤5.0E-7Pa·m³/s(1g/y)

7. Fully automatic detection process, easy operation

8. Human-machine interaction interface, convenient maintenance

: Next

Related Products

Product Consulting

Welcome to leave us a message, we will contact us as soon as possible!