Information Details

Unlocking the Science of Leak Detection: High Precision Helium Leak Detectors as Game Changers

Unlocking the Science of Leak Detection: High Precision Helium Leak Detectors as Game Changers Table of Contents 1. Introduction to Leak Detection 2. The Importance of Leak Detection in Various Industries 3. What Are High Precision Helium Leak Detectors? 4. The Technology Behind Helium Leak Detection 5. Applications of Helium Leak Detectors in Different Sectors 6. Advantag

Release time:

2025-09-16

Unlocking the Science of Leak Detection: High Precision Helium Leak Detectors as Game Changers

Table of Contents

- 1. Introduction to Leak Detection

- 2. The Importance of Leak Detection in Various Industries

- 3. What Are High Precision Helium Leak Detectors?

- 4. The Technology Behind Helium Leak Detection

- 5. Applications of Helium Leak Detectors in Different Sectors

- 6. Advantages of Using Helium Leak Detectors

- 7. Choosing the Right Helium Leak Detector

- 8. The Future of Leak Detection Technology

- 9. Frequently Asked Questions (FAQs)

- 10. Conclusion

1. Introduction to Leak Detection

Leak detection is a critical aspect of ensuring safety and efficiency across various industries, from manufacturing to pharmaceuticals. The process involves identifying unwanted leaks that can lead to catastrophic failures, safety hazards, and financial losses. Traditional methods of leak detection have served industries for decades; however, advancements in technology have ushered in a new era of precision and reliability. Among these advancements, **high precision helium leak detectors** stand out as essential tools that redefine how leaks are identified and quantified.

2. The Importance of Leak Detection in Various Industries

The implications of undetected leaks are vast and serious. In sectors like aerospace, automotive, and pharmaceuticals, even the smallest leak can lead to significant safety risks. For instance, leaks in gas lines can result in explosions, while small leaks in vacuum systems can compromise product integrity. Here’s a closer look at various industries:

Aerospace Industry

The aerospace industry relies heavily on **leak detection** for ensuring the integrity of fuel systems and life-support systems. Even minor leaks can lead to catastrophic outcomes.

Automotive Sector

In automotive manufacturing, detecting leaks in fuel systems and air conditioning units is vital for compliance with environmental standards and customer satisfaction.

Pharmaceuticals

Pharmaceutical companies must ensure that their products are free from contamination. Here, leak detection plays a crucial role in maintaining the integrity of sterile environments.

Manufacturing

In various manufacturing processes, leaks can lead to material waste and production downtime, impacting overall efficiency.

3. What Are High Precision Helium Leak Detectors?

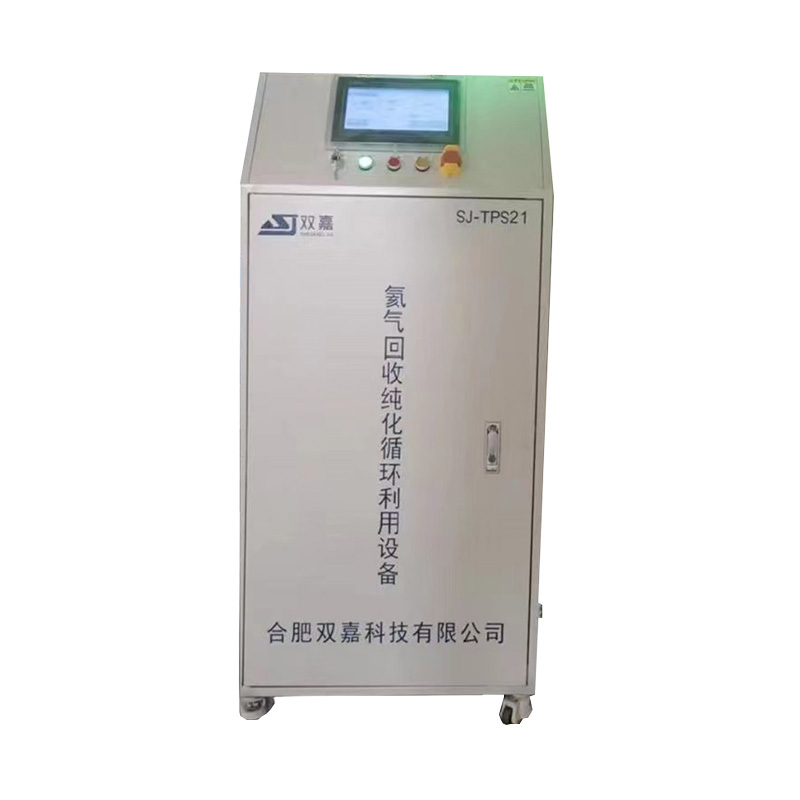

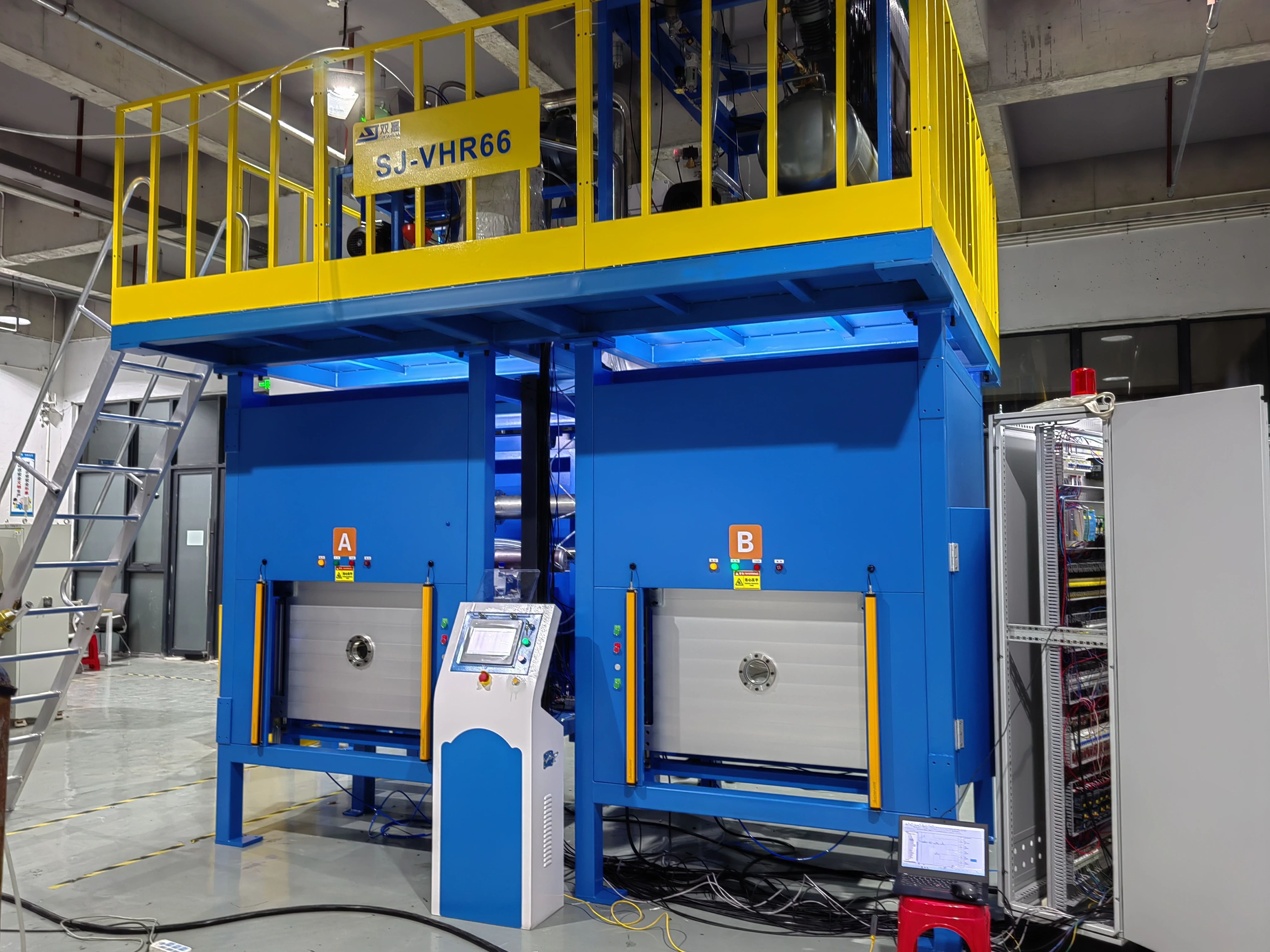

High precision helium leak detectors are specialized devices designed to identify and measure the presence of leaks in vacuum systems and gas applications. Utilizing helium as a tracer gas, these detectors can pinpoint even the most minute leaks with remarkable accuracy. Their high sensitivity and specificity make them invaluable in contexts where traditional methods may fall short.

4. The Technology Behind Helium Leak Detection

The operational principle of helium leak detectors is based on the unique properties of helium. Helium atoms are small and can easily escape through microscopic pores that larger molecules cannot penetrate. The detection process involves the following steps:

Helium Tracing

Helium is introduced into the system or component being tested. As the helium escapes through any leaks, it is drawn into the detector.

Mass Spectrometry

Once the helium enters the detector, it is analyzed using mass spectrometry. This technology can differentiate helium from other gases, ensuring accurate results.

Quantification and Reporting

The detector quantifies the amount of helium detected, allowing technicians to assess the severity of the leak accurately.

5. Applications of Helium Leak Detectors in Different Sectors

High precision helium leak detectors have a wide array of applications across various sectors:

Aerospace Testing

In aerospace, helium leak detectors are essential for testing fuel tanks and life-support systems, ensuring they meet stringent safety standards.

Automotive Components

In automotive manufacturing, these detectors are used to test air conditioning systems, fuel tanks, and exhaust systems for leaks.

Electronics Manufacturing

In the electronics sector, helium leak detection guarantees the integrity of hermetically sealed devices, such as sensors and transistors.

Medical Equipment

In the medical field, helium leak detectors are critical for ensuring the performance and safety of vital equipment, such as MRI machines and respiratory devices.

6. Advantages of Using Helium Leak Detectors

The use of high precision helium leak detectors offers several advantages over traditional leak detection methods:

High Sensitivity

Helium leak detectors can detect leaks as small as 1 x 10^-11 mbar l/s, making them the go-to choice for applications requiring extreme precision.

Speed and Efficiency

The speed at which these detectors operate allows for rapid leak testing without compromising accuracy, significantly enhancing workflow efficiency.

Environmentally Friendly

Helium is non-toxic and environmentally benign, making it a safe choice for leak detection without the risk of harmful emissions.

Versatility

High precision helium leak detectors are adaptable to a wide range of applications, from small-scale laboratory tests to large industrial systems.

7. Choosing the Right Helium Leak Detector

Selecting the appropriate helium leak detector involves considering several factors:

Application Requirements

Different applications may require varying levels of sensitivity, speed, and portability. Assessing your specific needs is vital.

Detector Specifications

Reviewing specifications such as detection range, response time, and the type of mass spectrometer is essential for optimal performance.

Manufacturer Reputation

Choosing a reputable manufacturer with a proven track record can ensure reliability and support, particularly in critical applications.

8. The Future of Leak Detection Technology

As industries continue to evolve, so too will leak detection technologies. Innovations in materials science, miniaturization of components, and advancements in data analytics are set to transform the landscape of leak detection. Emerging technologies like artificial intelligence and machine learning may enhance the accuracy and predictive capabilities of leak detection systems, making them even more indispensable.

9. Frequently Asked Questions (FAQs)

What is the primary advantage of using helium for leak detection?

Helium is advantageous due to its small atomic size, high sensitivity, and non-toxic nature, which allows for the detection of minute leaks in a variety of applications.

How do helium leak detectors compare to traditional methods?

Helium leak detectors offer higher sensitivity and faster results than traditional methods, making them more reliable for critical applications.

Can helium leak detectors be used in all industries?

While they are versatile, the specific application and environment must be considered to ensure compatibility and effectiveness.

What maintenance is required for helium leak detectors?

Regular calibration and maintenance checks are essential to ensure optimal performance and accuracy of helium leak detectors.

How does one know if they need a helium leak detector?

If your operations involve highly sensitive systems where leaks can lead to safety risks or significant financial losses, investing in a helium leak detector is advisable.

10. Conclusion

High precision helium leak detectors are truly game changers in the field of leak detection. Their unmatched sensitivity, speed, and versatility enable industries to proactively manage and mitigate the risks associated with leaks. As technology continues to advance, the significance of these detectors will only grow, solidifying their role as essential tools across various sectors. By investing in high precision helium leak detection technology, companies not only enhance safety and compliance but also improve operational efficiency and reliability.

High precision helium leak detector

Previous Page

Previous Page

Latest Blog