Information Details

Maximizing Efficiency: The Role of Helium Recovery Systems in Vacuum Chambers

Helium recovery systems are essential components in vacuum chamber applications, especially in industries relying on leak detection technologies. These systems are designed to capture and recycle helium, a noble gas that is often used to create the necessary vacuum environment in testing equipment. Understanding the functionality and benefits of helium recovery systems can significantly enhance op

Release time:

2025-09-11

Helium recovery systems are essential components in vacuum chamber applications, especially in industries relying on leak detection technologies. These systems are designed to capture and recycle helium, a noble gas that is often used to create the necessary vacuum environment in testing equipment. Understanding the functionality and benefits of helium recovery systems can significantly enhance operational efficiency and sustainability in various applications.

One of the primary advantages of employing a helium recovery system is the reduction of helium waste. Helium is a finite resource, and its extraction and transportation have environmental impacts. By implementing a recovery system, businesses can capture helium that would otherwise be lost during the testing processes. This not only conserves natural resources but also aligns with corporate sustainability initiatives, demonstrating a company's commitment to responsible resource management.

In addition to environmental considerations, helium recovery systems can lead to cost savings. The price of helium has seen fluctuations due to supply constraints, making it increasingly important for companies to manage this resource effectively. By recycling helium, businesses can reduce their dependency on external suppliers and mitigate the financial risks associated with helium price volatility. This can result in significant operational cost reductions over time, proving advantageous in competitive market landscapes.

Moreover, helium recovery systems enhance the accuracy and reliability of leak detection processes. In vacuum chamber applications, ensuring that the chamber maintains its integrity is crucial for achieving precise test results. A recovery system not only prevents helium loss but also ensures a consistent supply of helium for testing, which is vital for maintaining the integrity of the vacuum environment. This consistency plays a critical role in delivering accurate measurements and reliable performance in packaging tests.

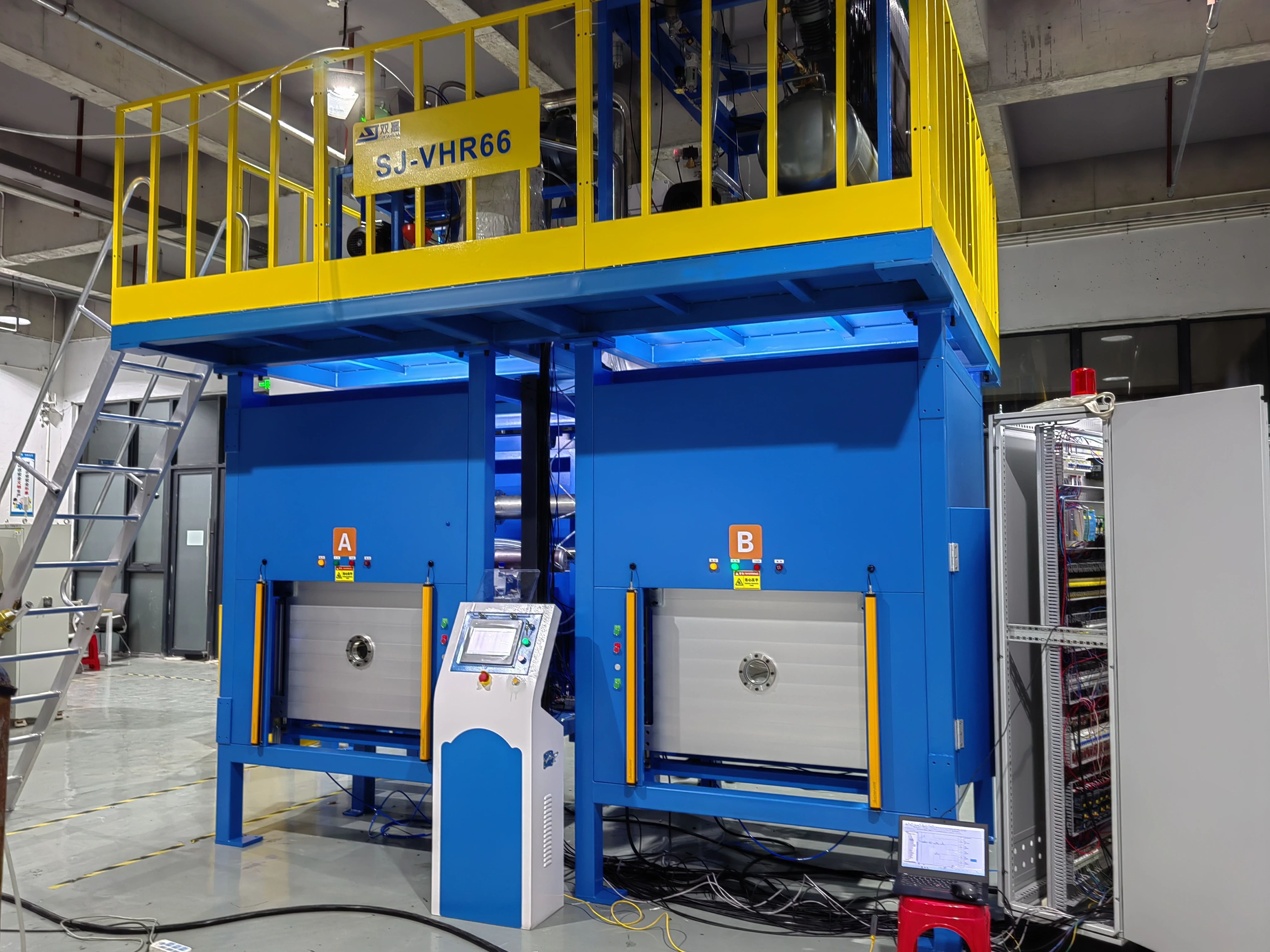

It’s important to consider the integration of helium recovery systems into existing vacuum chamber setups. Many modern systems are designed for easy installation and can be retrofitted to older equipment, making it feasible for businesses of all sizes to adopt this technology. Regular maintenance and monitoring of the recovery system will ensure optimal performance and longevity, further enhancing its benefits.

In conclusion, helium recovery systems for vacuum chambers represent a significant advancement in leak detection technology within the packaging testing equipment sector. By conserving resources, reducing costs, and ensuring accurate test results, these systems contribute to more sustainable and efficient operations. As industries continue to prioritize environmental responsibility and cost-effectiveness, the adoption of helium recovery systems will likely become increasingly prevalent.

One of the primary advantages of employing a helium recovery system is the reduction of helium waste. Helium is a finite resource, and its extraction and transportation have environmental impacts. By implementing a recovery system, businesses can capture helium that would otherwise be lost during the testing processes. This not only conserves natural resources but also aligns with corporate sustainability initiatives, demonstrating a company's commitment to responsible resource management.

In addition to environmental considerations, helium recovery systems can lead to cost savings. The price of helium has seen fluctuations due to supply constraints, making it increasingly important for companies to manage this resource effectively. By recycling helium, businesses can reduce their dependency on external suppliers and mitigate the financial risks associated with helium price volatility. This can result in significant operational cost reductions over time, proving advantageous in competitive market landscapes.

Moreover, helium recovery systems enhance the accuracy and reliability of leak detection processes. In vacuum chamber applications, ensuring that the chamber maintains its integrity is crucial for achieving precise test results. A recovery system not only prevents helium loss but also ensures a consistent supply of helium for testing, which is vital for maintaining the integrity of the vacuum environment. This consistency plays a critical role in delivering accurate measurements and reliable performance in packaging tests.

It’s important to consider the integration of helium recovery systems into existing vacuum chamber setups. Many modern systems are designed for easy installation and can be retrofitted to older equipment, making it feasible for businesses of all sizes to adopt this technology. Regular maintenance and monitoring of the recovery system will ensure optimal performance and longevity, further enhancing its benefits.

In conclusion, helium recovery systems for vacuum chambers represent a significant advancement in leak detection technology within the packaging testing equipment sector. By conserving resources, reducing costs, and ensuring accurate test results, these systems contribute to more sustainable and efficient operations. As industries continue to prioritize environmental responsibility and cost-effectiveness, the adoption of helium recovery systems will likely become increasingly prevalent.

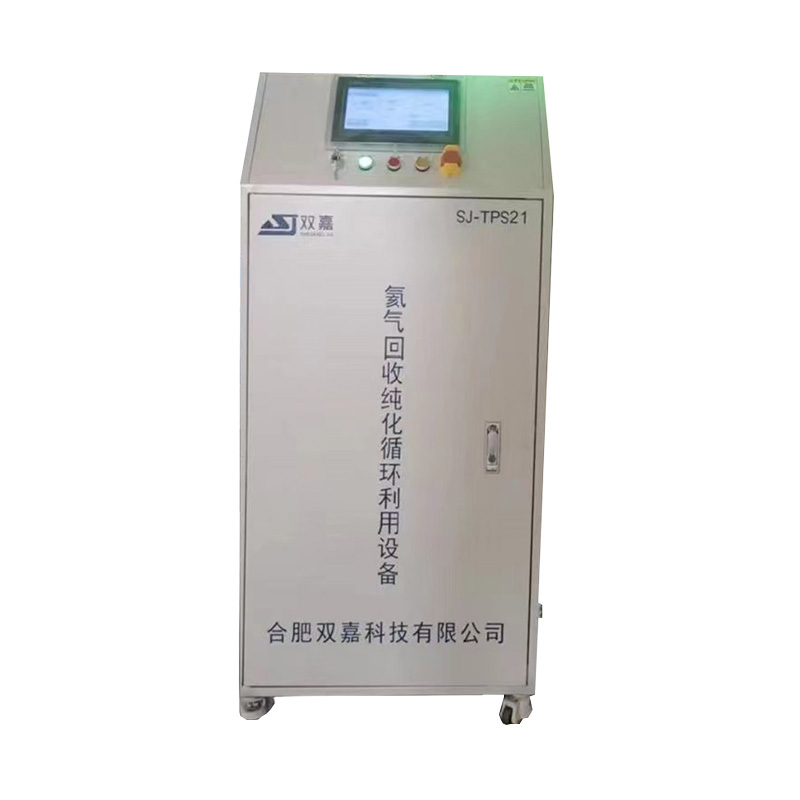

Helium recovery system for vacuum chamber

Latest Blog