Information Details

Unlocking Efficiency: The Importance of Helium Recovery Systems in Vacuum Chambers

Unlocking Efficiency: The Importance of Helium Recovery Systems in Vacuum Chambers Table of Contents 1. Introduction to Helium Recovery Systems 2. Understanding Vacuum Chambers 3. The Role of Helium in Vacuum Applications 4. Why Helium Recovery Systems Are Essential 5. Benefits of Helium Recovery Systems 5.1 Cost Efficiency 5.2 Environmental Su

Release time:

2025-09-06

Unlocking Efficiency: The Importance of Helium Recovery Systems in Vacuum Chambers

Table of Contents

- 1. Introduction to Helium Recovery Systems

- 2. Understanding Vacuum Chambers

- 3. The Role of Helium in Vacuum Applications

- 4. Why Helium Recovery Systems Are Essential

- 5. Benefits of Helium Recovery Systems

- 6. Components of Helium Recovery Systems

- 7. How to Choose the Right Helium Recovery System

- 8. Frequently Asked Questions

- 9. Conclusion

1. Introduction to Helium Recovery Systems

Helium recovery systems have become integral to the operation of vacuum chambers across various industries, particularly in instrumentation and packaging testing. These systems allow for the efficient collection and reuse of helium, a critical resource in many vacuum processes. As helium scarcity continues to be a pressing issue globally, the implementation of robust recovery systems not only enhances operational performance but also addresses environmental concerns.

2. Understanding Vacuum Chambers

Vacuum chambers are specially designed enclosures that create a low-pressure environment, essential for a range of applications, including scientific research, manufacturing, and testing. They are widely utilized in industries such as semiconductor fabrication, pharmaceuticals, and aerospace. Understanding the role of vacuum chambers and the processes they support is vital for appreciating the necessity of helium recovery systems.

3. The Role of Helium in Vacuum Applications

Helium is favored in vacuum applications due to its unique properties: it is inert, non-toxic, and has a low boiling point. These characteristics make it ideal for creating a stable vacuum environment and providing an effective way to cool components. Additionally, the use of helium in leak detection systems ensures the integrity of packaging in various industries, which is crucial for maintaining product quality and safety.

4. Why Helium Recovery Systems Are Essential

The necessity of helium recovery systems arises from several factors that impact both operational costs and environmental sustainability:

1. **Rising Helium Prices**: With the increasing demand and limited availability of helium, costs are on the rise. Implementing recovery systems can mitigate these expenses significantly.

2. **Environmental Responsibility**: As industries strive to minimize their carbon footprints, helium recovery systems contribute to sustainable practices by reducing waste and conserving resources.

3. **Operational Efficiency**: Efficient helium recovery enhances production capabilities and minimizes downtimes associated with helium shortages.

5. Benefits of Helium Recovery Systems

The implementation of helium recovery systems offers numerous advantages that enhance both operational processes and sustainability efforts.

5.1 Cost Efficiency

Helium recovery systems drastically reduce the amount of helium required for operations, leading to significant cost savings over time. By capturing and reusing helium, businesses can lower their consumption rates and decrease expenditures related to purchasing new helium supplies.

5.2 Environmental Sustainability

By facilitating the recycling of helium, these systems contribute to environmental sustainability goals. Reducing reliance on new helium supplies not only conserves resources but also diminishes the ecological footprint associated with helium extraction and production.

5.3 Operational Efficiency

Helium recovery systems improve operational efficiency by ensuring a consistent supply of helium. This reliability minimizes production interruptions, enhances workflow, and supports the overall efficacy of vacuum processes.

6. Components of Helium Recovery Systems

Understanding the key components of helium recovery systems can provide insights into their functionality and benefits. Here are the primary elements involved:

1. **Helium Collection Vessels**: These storage units capture helium during the vacuum process and store it for reuse.

2. **Compressors**: These devices compress the recovered helium, increasing its utility for various applications.

3. **Filtration Systems**: Filtration systems ensure that the recovered helium is clean and free from contaminants, maintaining quality standards.

4. **Monitoring Systems**: Advanced monitoring systems track helium levels, pressures, and other vital metrics to optimize performance.

7. How to Choose the Right Helium Recovery System

Selecting the appropriate helium recovery system requires careful consideration of several factors:

1. **Application Needs**: Assessing the specific requirements of your vacuum processes is crucial to determine the type and capacity of the recovery system needed.

2. **System Efficiency**: Researching the efficiency ratings of potential systems can help ensure that you invest in a solution that maximizes helium recovery.

3. **Maintenance Requirements**: Consider the maintenance needs of various systems to ensure long-term viability and performance.

4. **Cost-Benefit Analysis**: Conducting a thorough analysis of costs versus benefits will aid in making informed decisions that align with budgetary constraints.

8. Frequently Asked Questions

8.1 What are the main advantages of using helium recovery systems?

Helium recovery systems enhance cost efficiency, promote environmental sustainability, and improve operational efficiency in vacuum processes.

8.2 How much helium can be recovered using these systems?

The amount of helium recovered depends on the efficiency of the system and the specific application, but many systems can reclaim up to 90% of the helium used.

8.3 Are helium recovery systems expensive to install?

While there is an initial investment involved, the long-term savings from reduced helium costs often outweigh the installation expenses.

8.4 What maintenance is required for helium recovery systems?

Regular maintenance includes checking filters, monitoring system performance, and servicing compressors to ensure optimal functioning.

8.5 Can helium recovery systems be integrated into existing vacuum setups?

Yes, many helium recovery systems are designed for easy integration with existing vacuum chambers and can enhance their performance significantly.

9. Conclusion

Helium recovery systems are vital for maximizing efficiency in vacuum chambers, particularly in industries reliant on instrumentation and packaging testing. By understanding the importance of these systems, businesses can not only reduce operational costs but also contribute to environmental sustainability initiatives. Investing in helium recovery technology is a strategic move that enhances both productivity and ecological responsibility, leading to a more efficient and sustainable future.

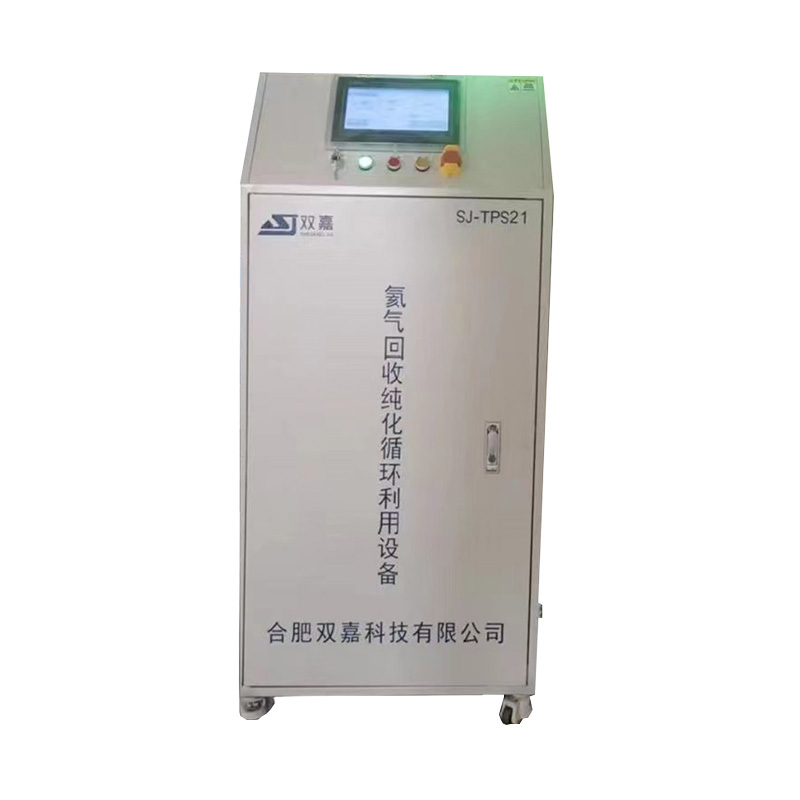

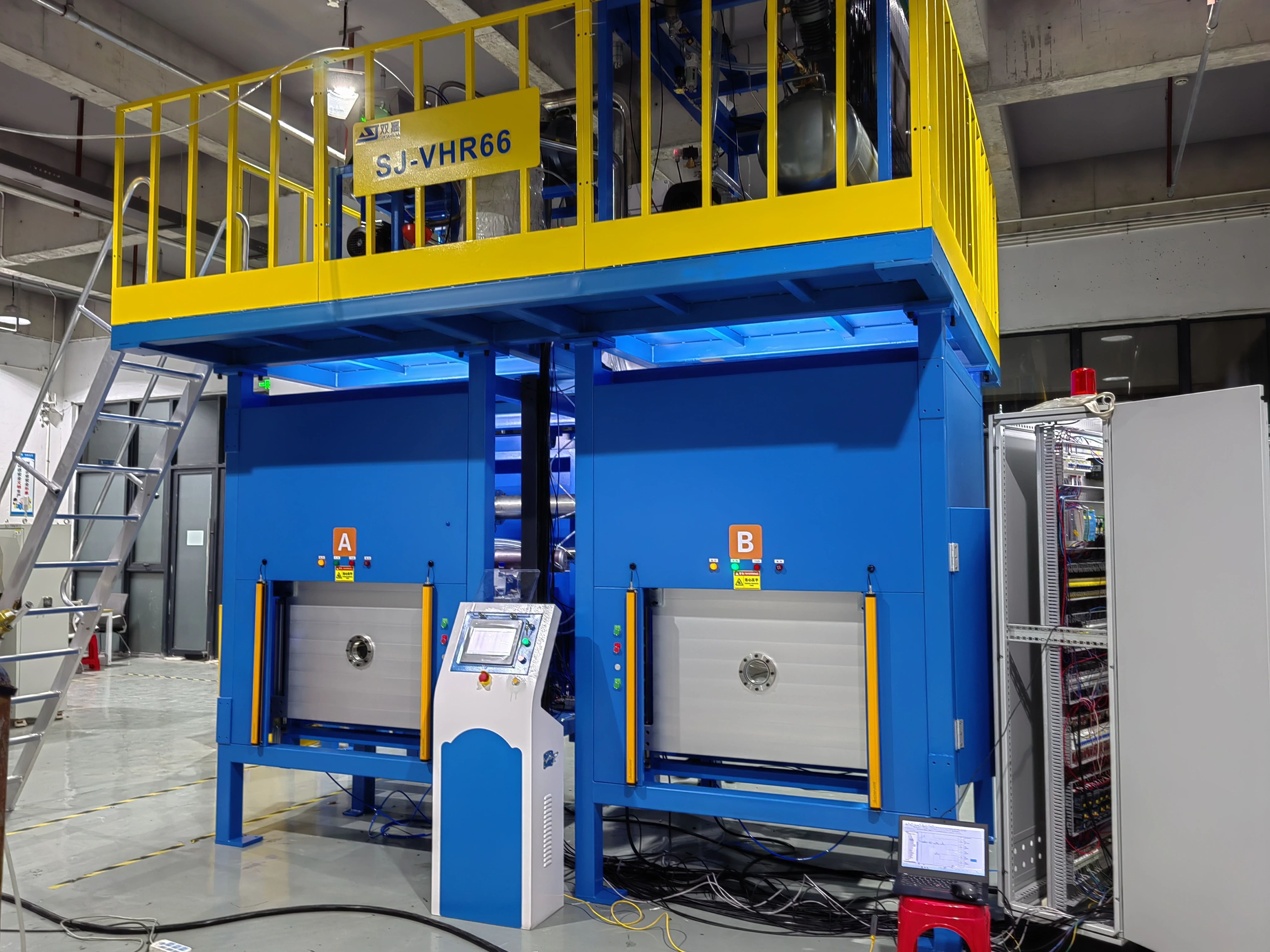

Helium recovery system for vacuum chamber

Latest Blog