Information Details

The Essential Guide to High Precision Helium Leak Detectors for Effective Leak Testing

High precision helium leak detectors are vital instruments used in various industries to identify leaks in sealed packages, containers, and systems. These detectors work by utilizing helium—a gas that is both light and non-reactive—allowing for highly sensitive detection of even the smallest leaks. This makes them an invaluable tool in fields such as pharmaceuticals, aerospace, automotive, and ele

Release time:

2025-09-21

High precision helium leak detectors are vital instruments used in various industries to identify leaks in sealed packages, containers, and systems. These detectors work by utilizing helium—a gas that is both light and non-reactive—allowing for highly sensitive detection of even the smallest leaks. This makes them an invaluable tool in fields such as pharmaceuticals, aerospace, automotive, and electronics, where maintaining product integrity is crucial.

One of the primary reasons for employing helium leak detection is its unmatched sensitivity. High precision helium leak detectors can detect leaks as small as 1 x 10^-12 mbar L/s, which is far superior to many other leak detection methods. This capability is essential for applications where even minute leaks can lead to product failure, safety concerns, or compliance issues. The ability to detect such tiny leaks ensures that products are reliable and meet stringent industry standards.

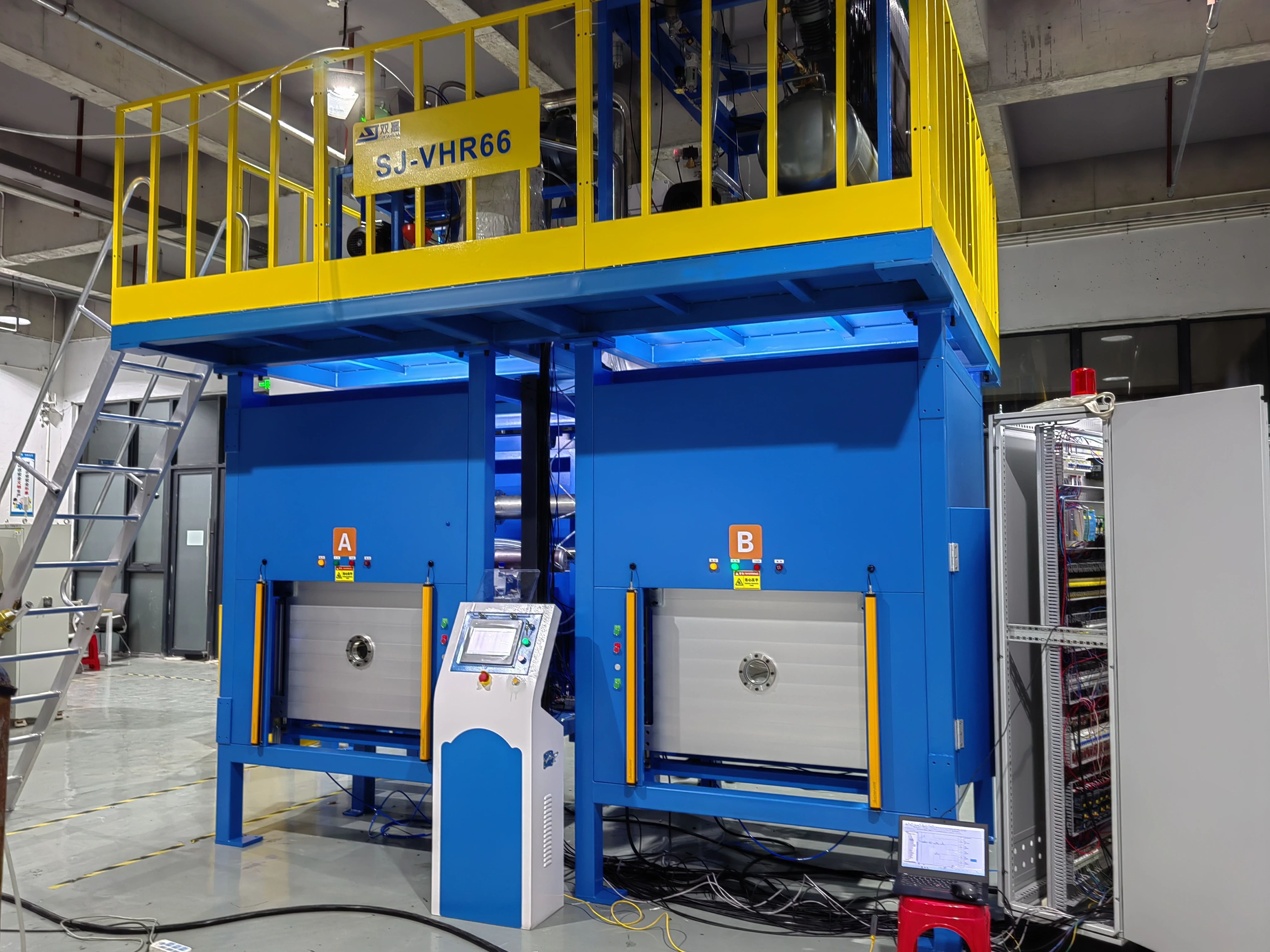

The operation of a helium leak detector typically involves several key steps. First, the system or package being tested is evacuated of air and filled with helium. The detector is then used to check for the presence of helium escaping from the test object. If helium is detected, it indicates a leak, allowing for precise identification and remediation. This process is efficient, often yielding results in real-time, which is essential for quality control in manufacturing environments.

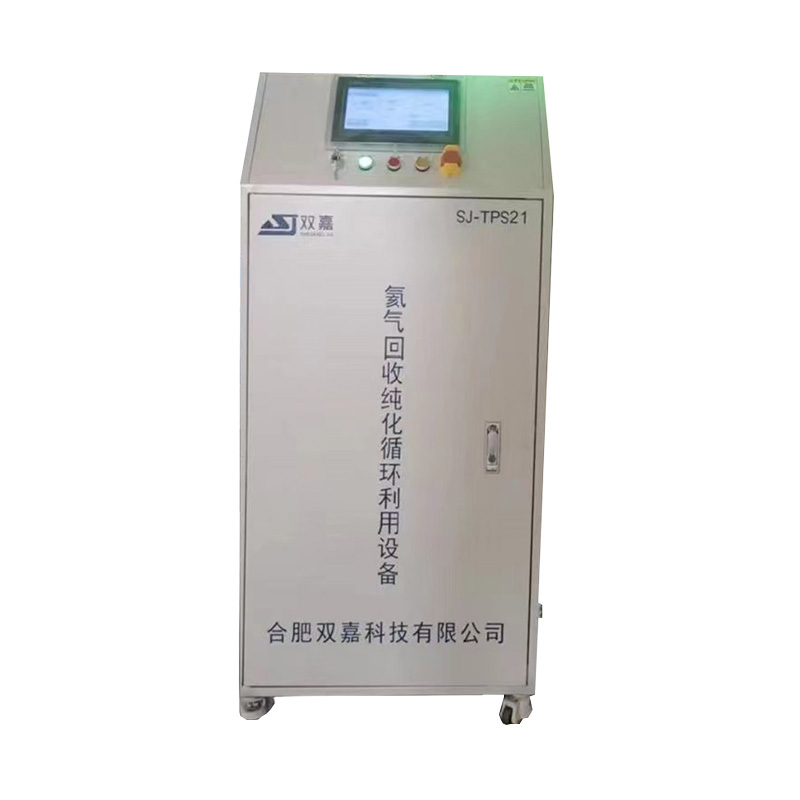

In addition to their sensitivity, high precision helium leak detectors offer a range of features that enhance their usability. Many models come with user-friendly interfaces, data logging capabilities, and options for remote monitoring. These features make it easier for operators to analyze leak test results and track performance over time. Furthermore, some detectors are designed to be portable, allowing for on-site testing in various environments.

The applications of high precision helium leak detectors are vast. In the pharmaceutical industry, they are crucial for ensuring the integrity of sterile packaging. In the aerospace sector, they help maintain the safety and reliability of critical components. In the automotive industry, these detectors can identify leaks in fuel systems, air conditioning units, and more, ensuring optimal performance and safety.

In conclusion, high precision helium leak detectors play a critical role in leak testing across multiple industries. Their unparalleled sensitivity, efficiency, and advanced features make them essential tools for maintaining product integrity and ensuring compliance with regulatory standards. Whether used in manufacturing, research, or quality control, these detectors are invaluable for identifying leaks that could compromise product performance and safety. By investing in high precision helium leak detection technology, businesses can enhance their operational efficiency and uphold their commitment to quality.

One of the primary reasons for employing helium leak detection is its unmatched sensitivity. High precision helium leak detectors can detect leaks as small as 1 x 10^-12 mbar L/s, which is far superior to many other leak detection methods. This capability is essential for applications where even minute leaks can lead to product failure, safety concerns, or compliance issues. The ability to detect such tiny leaks ensures that products are reliable and meet stringent industry standards.

The operation of a helium leak detector typically involves several key steps. First, the system or package being tested is evacuated of air and filled with helium. The detector is then used to check for the presence of helium escaping from the test object. If helium is detected, it indicates a leak, allowing for precise identification and remediation. This process is efficient, often yielding results in real-time, which is essential for quality control in manufacturing environments.

In addition to their sensitivity, high precision helium leak detectors offer a range of features that enhance their usability. Many models come with user-friendly interfaces, data logging capabilities, and options for remote monitoring. These features make it easier for operators to analyze leak test results and track performance over time. Furthermore, some detectors are designed to be portable, allowing for on-site testing in various environments.

The applications of high precision helium leak detectors are vast. In the pharmaceutical industry, they are crucial for ensuring the integrity of sterile packaging. In the aerospace sector, they help maintain the safety and reliability of critical components. In the automotive industry, these detectors can identify leaks in fuel systems, air conditioning units, and more, ensuring optimal performance and safety.

In conclusion, high precision helium leak detectors play a critical role in leak testing across multiple industries. Their unparalleled sensitivity, efficiency, and advanced features make them essential tools for maintaining product integrity and ensuring compliance with regulatory standards. Whether used in manufacturing, research, or quality control, these detectors are invaluable for identifying leaks that could compromise product performance and safety. By investing in high precision helium leak detection technology, businesses can enhance their operational efficiency and uphold their commitment to quality.

High precision helium leak detector

Latest Blog