Information Details

Maximizing Efficiency: Understanding Helium Recovery Systems for Vacuum Chambers

In the realm of vacuum technology, particularly within the packaging testing and leak detection industries, helium recovery systems have emerged as vital components. These systems are designed to capture and recycle helium, a noble gas frequently used for leak testing due to its unique properties. Understanding how helium recovery systems function can greatly enhance operational efficiency and con

Release time:

2025-09-01

In the realm of vacuum technology, particularly within the packaging testing and leak detection industries, helium recovery systems have emerged as vital components. These systems are designed to capture and recycle helium, a noble gas frequently used for leak testing due to its unique properties. Understanding how helium recovery systems function can greatly enhance operational efficiency and contribute to sustainability efforts.

Helium is an excellent tracer gas because it is non-toxic, non-flammable, and has a low molecular weight, making it ideal for detecting leaks in vacuum chambers. However, helium is also a finite resource, and its extraction involves significant environmental impact and cost. This is where helium recovery systems come into play. By reclaiming helium that would otherwise be lost during the testing process, these systems minimize waste and reduce the need for new helium.

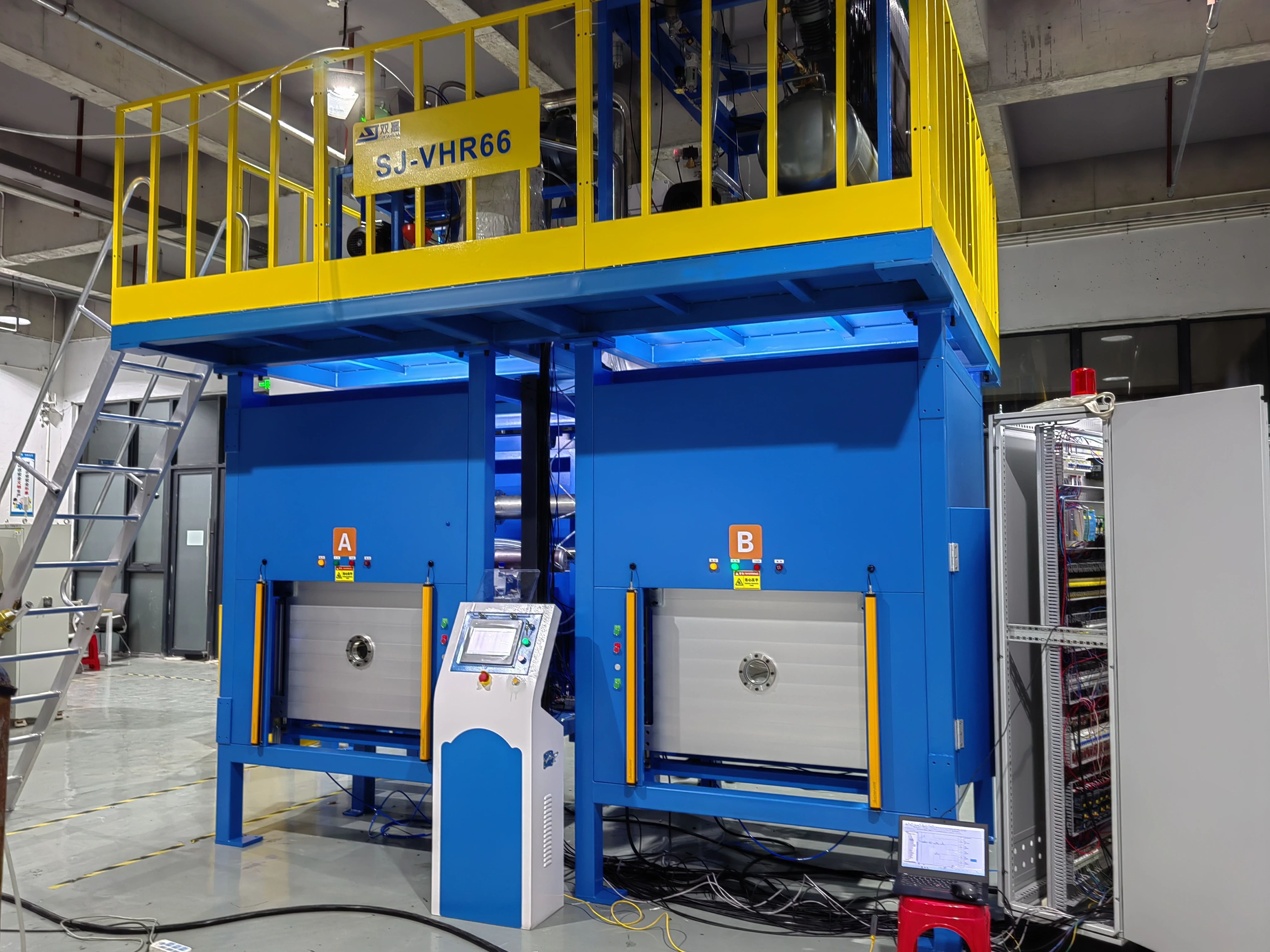

A helium recovery system typically consists of a series of components that work together to capture and compress the gas. When helium is used in a vacuum chamber for leak testing, it can escape into the atmosphere if not properly managed. The recovery system is designed to collect this escaping helium, compress it, and store it for future use. This not only reduces the overall consumption of helium but also lowers operational costs associated with purchasing new gas.

Implementing a helium recovery system can lead to notable efficiency gains. For instance, by recycling helium, companies can significantly decrease their helium expenses, which can be particularly advantageous given the fluctuating prices of helium in the market. Additionally, these systems can enhance testing accuracy and reliability. By ensuring that the available helium is reused effectively, the conditions in the vacuum chamber remain consistent, leading to more precise leak detection results.

Moreover, the environmental benefits cannot be overlooked. With growing awareness of sustainability, businesses are increasingly seeking ways to minimize their carbon footprint. By adopting helium recovery systems, companies not only comply with environmental regulations but also demonstrate their commitment to responsible resource management.

In summary, helium recovery systems for vacuum chambers play a crucial role in enhancing efficiency and sustainability in the packaging testing and leak detection industry. By capturing and recycling helium, these systems reduce operational costs, improve testing accuracy, and support environmental stewardship. As industries continue to evolve, the adoption of such technologies will likely become a standard practice, making helium recovery systems an essential consideration for any organization involved in vacuum technology.

Helium is an excellent tracer gas because it is non-toxic, non-flammable, and has a low molecular weight, making it ideal for detecting leaks in vacuum chambers. However, helium is also a finite resource, and its extraction involves significant environmental impact and cost. This is where helium recovery systems come into play. By reclaiming helium that would otherwise be lost during the testing process, these systems minimize waste and reduce the need for new helium.

A helium recovery system typically consists of a series of components that work together to capture and compress the gas. When helium is used in a vacuum chamber for leak testing, it can escape into the atmosphere if not properly managed. The recovery system is designed to collect this escaping helium, compress it, and store it for future use. This not only reduces the overall consumption of helium but also lowers operational costs associated with purchasing new gas.

Implementing a helium recovery system can lead to notable efficiency gains. For instance, by recycling helium, companies can significantly decrease their helium expenses, which can be particularly advantageous given the fluctuating prices of helium in the market. Additionally, these systems can enhance testing accuracy and reliability. By ensuring that the available helium is reused effectively, the conditions in the vacuum chamber remain consistent, leading to more precise leak detection results.

Moreover, the environmental benefits cannot be overlooked. With growing awareness of sustainability, businesses are increasingly seeking ways to minimize their carbon footprint. By adopting helium recovery systems, companies not only comply with environmental regulations but also demonstrate their commitment to responsible resource management.

In summary, helium recovery systems for vacuum chambers play a crucial role in enhancing efficiency and sustainability in the packaging testing and leak detection industry. By capturing and recycling helium, these systems reduce operational costs, improve testing accuracy, and support environmental stewardship. As industries continue to evolve, the adoption of such technologies will likely become a standard practice, making helium recovery systems an essential consideration for any organization involved in vacuum technology.

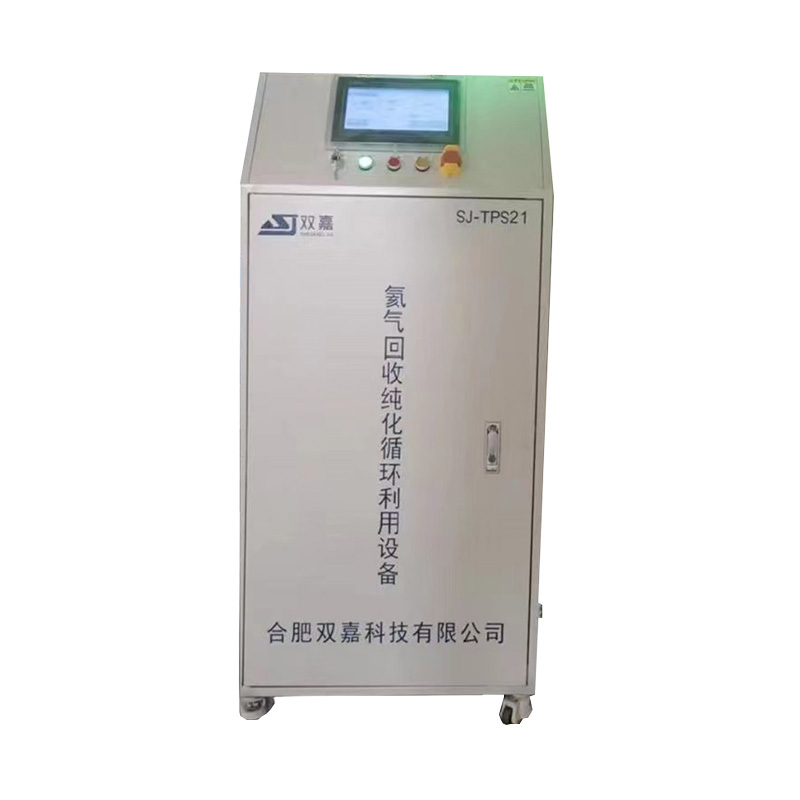

Helium recovery system for vacuum chamber

Latest Blog