Information Details

Top Benefits of Using an Integrated Helium Leak Detection System

Top Benefits of Using an Integrated Helium Leak Detection System In the modern manufacturing landscape, ensuring product integrity and safety is paramount. One of the most effective methods for detecting leaks in various applications is through the use of integrated helium leak detection systems. These advanced systems leverage helium's unique properties to identify the smallest leaks, providing

Release time:

2025-08-27

Top Benefits of Using an Integrated Helium Leak Detection System

In the modern manufacturing landscape, ensuring product integrity and safety is paramount. One of the most effective methods for detecting leaks in various applications is through the use of integrated helium leak detection systems. These advanced systems leverage helium's unique properties to identify the smallest leaks, providing companies with a reliable solution for maintaining quality control. In this article, we outline the **top benefits of using an integrated helium leak detection system**, shedding light on how it can transform your operations.

Table of Contents

- 1. Understanding Helium Leak Detection

- 2. Enhanced Accuracy in Leak Detection

- 3. Improved Efficiency and Speed

- 4. Cost-Effectiveness of Integrated Systems

- 5. Versatility Across Industries

- 6. Compliance with Industry Standards

- 7. User-Friendly Interfaces and Integration

- 8. Conclusion

- 9. Frequently Asked Questions

1. Understanding Helium Leak Detection

Helium leak detection is a sophisticated method widely recognized for its precision. Helium has a small atomic size, enabling it to pass through minute openings that may not be detectable by other methods. An integrated helium leak detection system combines advanced technology with helium's properties to deliver superior leak detection capabilities. This system is crucial for various sectors, including aerospace, automotive, and pharmaceuticals, where product reliability is non-negotiable.

2. Enhanced Accuracy in Leak Detection

One of the primary benefits of using an integrated helium leak detection system is its **enhanced accuracy**. Traditional leak detection methods may overlook small leaks, resulting in product failures and safety issues. Integrated systems can detect leaks as small as 1x10^-11 mbar l/s, allowing for **precise measurements** and immediate adjustments to manufacturing processes.

With the ability to differentiate between various leak types, these systems provide valuable insights into potential failure points. This level of accuracy not only enhances product quality but also instills confidence in stakeholders regarding safety and reliability.

3. Improved Efficiency and Speed

In a competitive marketplace, **efficiency** is essential. Integrated helium leak detection systems significantly streamline the leak testing process. The rapid response times of these systems mean that leaks can be identified and addressed in real time, reducing downtime and enhancing productivity.

Moreover, the automated nature of these systems allows for continuous monitoring, ensuring that potential leaks are detected before they escalate into costly problems. This efficiency translates into a more streamlined workflow, allowing companies to focus on meeting production targets without compromising quality.

4. Cost-Effectiveness of Integrated Systems

Investing in an integrated helium leak detection system can lead to substantial long-term **cost savings**. Although the initial investment may be higher compared to traditional methods, the return on investment (ROI) is significant. By reducing the amount of wasted materials and minimizing product recalls, companies can save money while simultaneously improving their bottom line.

Additionally, the durability and reliability of these systems mean less frequent replacements and maintenance costs, further solidifying their **cost-effectiveness** over time.

5. Versatility Across Industries

An integrated helium leak detection system is not limited to a specific sector; its versatility makes it suitable for various industries. From **aerospace** to **automotive**, and **medical device manufacturing**, these systems can be adapted to meet diverse operational requirements.

In the pharmaceutical industry, for instance, ensuring the integrity of packaging is critical to maintaining drug efficacy. An integrated leak detection system can help manufacturers ensure that their products meet stringent regulatory requirements, thereby protecting public health and safety.

6. Compliance with Industry Standards

Compliance with industry standards is a crucial aspect of manufacturing. An integrated helium leak detection system helps businesses adhere to regulations set forth by governing bodies such as ISO, FDA, and other industry-specific standards. By utilizing a system known for its accuracy and reliability, companies can demonstrate their commitment to quality and safety.

This compliance not only protects consumers but also enhances a company’s reputation. In today’s discerning market, being recognized for maintaining high standards can differentiate a business from its competitors.

7. User-Friendly Interfaces and Integration

Modern integrated helium leak detection systems are designed with the user in mind. Many systems feature **intuitive interfaces** that simplify the testing process, reducing the learning curve for new users. This user-friendliness ensures that personnel can operate the systems effectively, minimizing errors during testing.

Furthermore, these systems can often be integrated with existing production line equipment and software, facilitating seamless operations. The ease of integration allows companies to adopt this advanced technology without overhauling their current infrastructure.

8. Conclusion

The benefits of utilizing an integrated helium leak detection system are profound. From **enhanced accuracy** and **increased efficiency** to significant **cost savings** and **compliance with industry standards**, these systems represent a vital investment for businesses across various sectors. As industries continue to prioritize quality and safety, adopting advanced leak detection technology will become increasingly important. Transitioning to an integrated helium leak detection system is not just a smart choice; it's a necessary step towards future-proofing operations in a competitive market.

9. Frequently Asked Questions

What is an integrated helium leak detection system?

An integrated helium leak detection system uses helium's unique properties to identify and measure leaks in various applications. These systems offer high precision and are widely used in industries requiring strict quality control.

How does helium leak detection work?

Helium leak detection works by introducing helium gas into a sealed environment. The system then uses sensitive detectors to identify and measure any helium that escapes through leaks, providing accurate leak rates.

Why is helium used for leak detection?

Helium is used for leak detection due to its small atomic size and inert properties. This allows it to penetrate tiny openings that other gases cannot, making it an ideal choice for precise measurements.

What industries benefit most from helium leak detection?

Industries such as aerospace, automotive, pharmaceuticals, and medical device manufacturing significantly benefit from helium leak detection due to the critical nature of product integrity and safety.

How can I ensure compliance with industry standards using helium leak detection?

Using an integrated helium leak detection system helps ensure compliance with industry standards such as ISO and FDA by providing reliable and accurate testing results that meet regulatory requirements.

By understanding and leveraging the benefits of integrated helium leak detection systems, businesses can enhance their operational efficiency and uphold the highest standards of quality and safety.

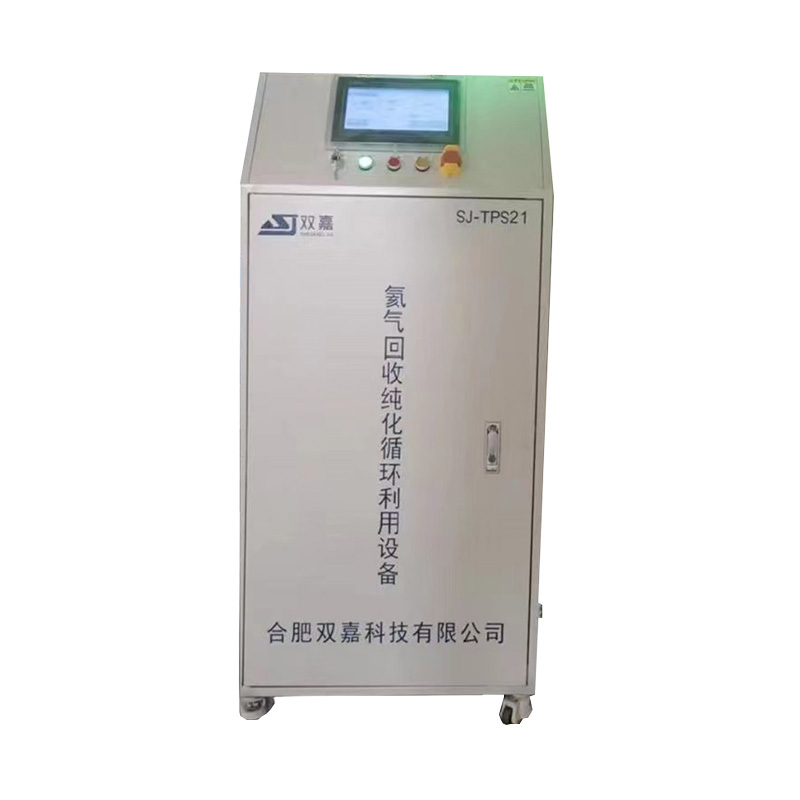

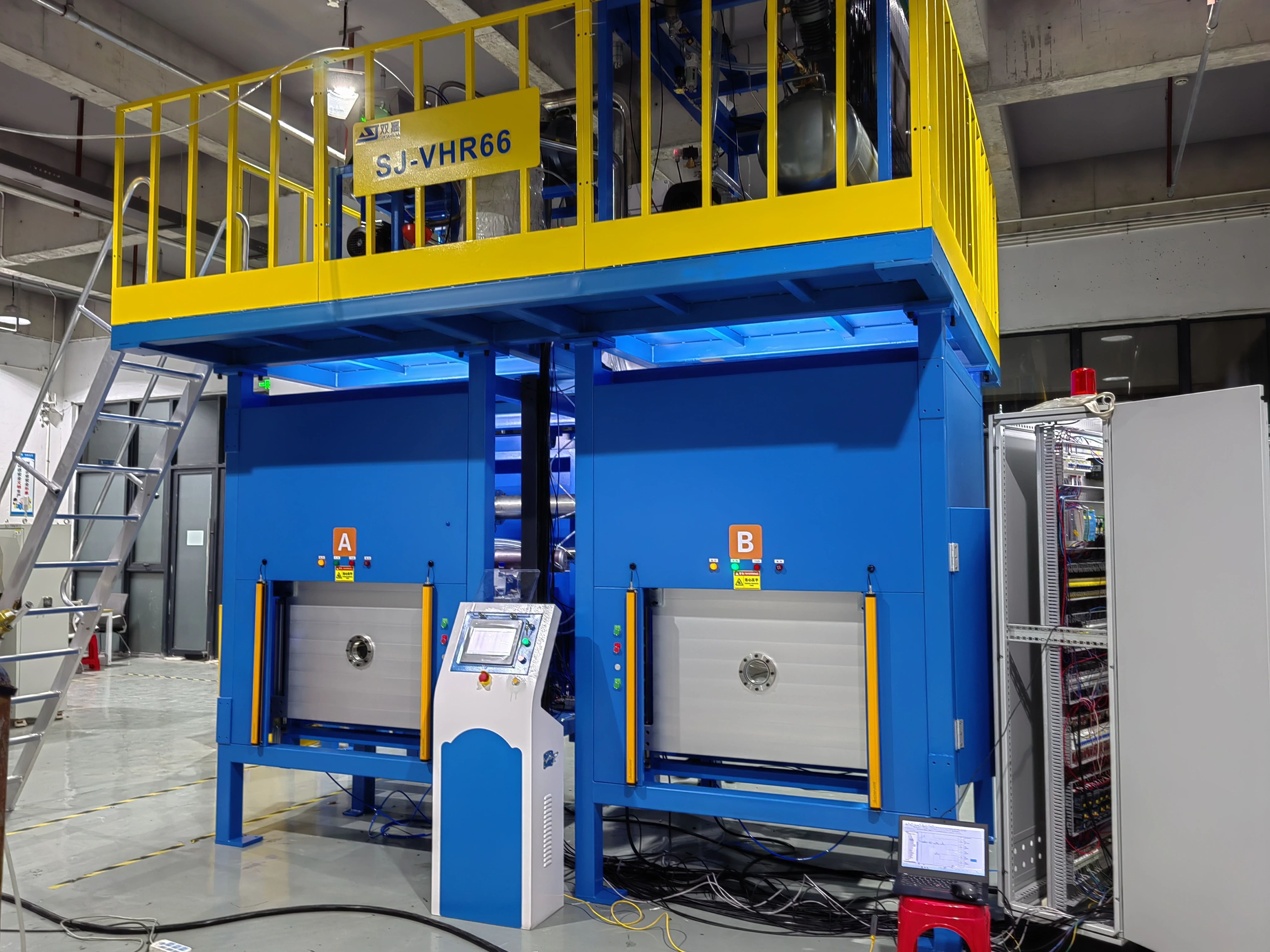

Integrated helium leak detection machine

Latest Blog