Information Details

Unlocking the Secrets of Vacuum Chambers with Helium Gas Analyzers: A Comprehensive Guide

Unlocking the Secrets of Vacuum Chambers with Helium Gas Analyzers Table of Contents 1. Understanding Vacuum Chambers: The Basics 2. The Role of Helium Gas Analyzers in Vacuum Technology 3. How Vacuum Chambers Work: Principles and Mechanics 4. The Importance of Leak Detection in Vacuum Systems 5. Advantages of Using Helium for Leak Testing 5.1. Helium's Unique Properties 5.2. Helium vs. Other Leak

Release time:

2025-11-29

Unlocking the Secrets of Vacuum Chambers with Helium Gas Analyzers

Table of Contents

1. Understanding Vacuum Chambers: The Basics

2. The Role of Helium Gas Analyzers in Vacuum Technology

3. How Vacuum Chambers Work: Principles and Mechanics

4. The Importance of Leak Detection in Vacuum Systems

5. Advantages of Using Helium for Leak Testing

5.1. Helium's Unique Properties

5.2. Helium vs. Other Leak Detection Methods

6. Choosing the Right Helium Gas Analyzer

6.1. Key Features to Consider

6.2. Applications Across Different Industries

7. Best Practices for Using Helium Gas Analyzers

8. Frequently Asked Questions (FAQs)

9. Conclusion

1. Understanding Vacuum Chambers: The Basics

Vacuum chambers are essential components in various industries, from semiconductor manufacturing to laboratory research. These sealed environments allow for controlled conditions by removing air and other gases, resulting in a vacuum. By manipulating atmospheric pressure, vacuum chambers facilitate numerous processes, including chemical reactions, material testing, and electronic device fabrication.

A vacuum chamber can vary in design based on its intended application, but the fundamental principle remains the same: creating a space devoid of matter. The efficiency of vacuum systems relies heavily on their ability to maintain low-pressure environments, which is where helium gas analyzers come into play.

2. The Role of Helium Gas Analyzers in Vacuum Technology

Helium gas analyzers are specialized instruments designed to detect leaks in vacuum systems. These analyzers utilize the unique properties of helium as a tracer gas to identify even the smallest leaks. When a vacuum chamber is subjected to helium, any escaping helium gas indicates a breach in the chamber's integrity.

These analyzers are crucial for ensuring the reliability and performance of vacuum systems. By pinpointing leaks, technicians can address issues before they escalate, saving time and reducing costs associated with equipment failure and production downtime.

3. How Vacuum Chambers Work: Principles and Mechanics

Understanding the mechanics of vacuum chambers is vital to appreciating the importance of helium gas analyzers. A vacuum chamber typically consists of a sealed enclosure, a vacuum pump, and various valves and gauges. The vacuum pump removes air and gas from the chamber, creating a low-pressure environment.

The success of this process is contingent upon several factors:

- **Material Selection**: The construction materials must be compatible with the intended application to prevent reactions or contamination.

- **Seals and Joints**: High-quality seals are vital to maintaining vacuum integrity. Weak seals are common points of leakage.

- **Pump Efficiency**: The type and efficiency of the vacuum pump determine how quickly and effectively a vacuum is achieved.

Regular maintenance and testing, including the use of helium gas analyzers, are essential for ensuring that vacuum chambers function optimally.

4. The Importance of Leak Detection in Vacuum Systems

Leak detection is a critical component of maintaining vacuum system integrity. Even the smallest leaks can compromise a vacuum chamber's performance, leading to significant issues such as contamination, process inefficiencies, and product defects.

Implementing a robust leak detection strategy is essential for:

- **Quality Assurance**: Ensuring that products are manufactured under controlled conditions.

- **Cost Efficiency**: Minimizing waste and rework associated with leaks.

- **Operational Safety**: Preventing hazardous situations that can arise from compromised vacuum conditions.

A helium gas analyzer is an indispensable tool in this strategy, offering precise leak detection capabilities.

5. Advantages of Using Helium for Leak Testing

Helium is widely regarded as the preferred tracer gas for leak detection in vacuum systems. Its unique properties make it particularly effective.

5.1. Helium's Unique Properties

Helium is an inert, non-toxic gas that is lighter than air. Its small atomic size allows it to permeate through minute openings, making it an ideal choice for identifying leaks that other gases cannot detect. Furthermore, its high thermal conductivity enhances the speed and efficiency of leak detection processes.

5.2. Helium vs. Other Leak Detection Methods

While several methods exist for leak detection, including mass spectrometry and pressure decay, helium detection offers distinct advantages:

- **Sensitivity**: Helium gas analyzers can detect leaks as small as 1 x 10^-9 mbar L/s.

- **Speed**: Helium testing is rapid and can be completed in real-time.

- **Versatility**: These analyzers can be used in various applications, from industrial equipment to research laboratories.

Given these advantages, helium gas analyzers have become the gold standard for leak detection.

6. Choosing the Right Helium Gas Analyzer

Selecting the appropriate helium gas analyzer involves considering several factors aligned with your specific requirements.

6.1. Key Features to Consider

When evaluating helium gas analyzers, take into account the following features:

- **Sensitivity and Range**: Ensure the analyzer can detect the specific range of leak rates pertinent to your applications.

- **Response Time**: Fast response times can significantly enhance operational efficiency.

- **Portability**: If on-site testing is required, consider the size and weight of the analyzer.

6.2. Applications Across Different Industries

Helium gas analyzers find applications in various sectors, including:

- **Semiconductor Manufacturing**: Ensuring the integrity of vacuum systems used in chip fabrication.

- **Aerospace**: Testing the vacuum conditions in spacecraft and satellite systems.

- **Medical Device Production**: Verifying the quality of vacuum-sealed packaging.

Understanding the applications can guide your selection process, ensuring you choose a model best suited for your needs.

7. Best Practices for Using Helium Gas Analyzers

To maximize the effectiveness of helium gas analyzers, adhere to the following best practices:

- **Regular Calibration**: Ensure the analyzer is calibrated according to the manufacturer's specifications for accurate readings.

- **Consistent Maintenance**: Conduct routine maintenance checks to keep the analyzer in optimal condition.

- **Proper Training**: Ensure that personnel are trained in the operation of the analyzer to reduce the risk of errors.

By implementing these practices, users can enhance the reliability of their leak detection efforts.

8. Frequently Asked Questions (FAQs)

What is a vacuum chamber used for?

Vacuum chambers are utilized in various applications, including material testing, semiconductor fabrication, and scientific research, where controlled low-pressure environments are essential.

How does a helium gas analyzer work?

A helium gas analyzer detects leaks by introducing helium into the vacuum chamber. The analyzer measures the concentration of helium inside the chamber to identify any leaks.

Why is helium preferred for leak detection?

Helium is preferred due to its small atomic size, inert nature, and ability to detect minute leaks that other gases cannot identify.

What industries benefit from helium gas analyzers?

Industries such as semiconductor manufacturing, aerospace, and medical device production benefit significantly from helium gas analyzers.

How often should vacuum systems be tested for leaks?

Regular testing is recommended, with the frequency depending on the specific application and industry standards. However, it is advisable to conduct tests whenever maintenance is performed or when there are changes in operating conditions.

9. Conclusion

Understanding the relationship between vacuum chambers and helium gas analyzers is pivotal for maintaining operational efficiency across various industries. Helium gas analyzers, with their unique capabilities, provide a reliable means of leak detection, ensuring that vacuum systems function optimally. By employing best practices and choosing the right equipment, organizations can enhance their processes, reduce costs, and improve product quality. As technology advances, the role of helium gas analyzers will likely become even more critical in ensuring the integrity and reliability of vacuum systems.

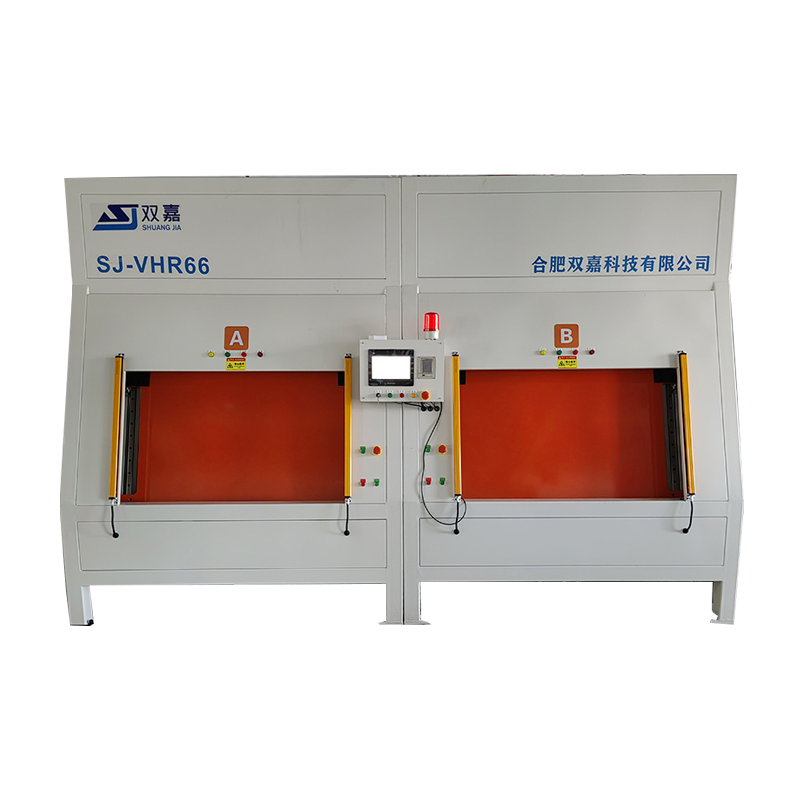

Helium gas analyzer for vacuum chamber

Latest Blog

![[Leak Detection] The Influence of Different Gases and Pressures on Vacuum Leak Rates [Leak Detection] The Influence of Different Gases and Pressures on Vacuum Leak Rates](https://omo-oss-image.thefastimg.com/portal-saas/pg2025011513462602974/cms/image/d5d191ab-e7d1-4327-9cee-c1da43b8cc36.png)